Are you ready to upgrade your car maintenance skills? Today, we’ll dive into the fascinating world of changing disc brake pads. Picture this: you’re cruising down the road with the wind in your hair when suddenly, you need to make a quick stop. Your heart pounds as you press the brake pedal, but nothing happens. Don’t fret! Understanding how to change disc brake pads can save the day and keep you safe on the streets.

So, what exactly are disc brake pads? Think of them as the unsung heroes of your car’s braking system. They are small but mighty components that create friction against the spinning brake rotor, slowing down or stopping your vehicle. Over time, these pads wear out due to the immense heat and pressure they endure. That’s why it’s essential to know how to replace them.

Before you embark on this mechanical adventure, gather your tools: a lug wrench, a jack, jack stands, a C-clamp, and, of course, new brake pads. Safety first! Park your car on a level surface and engage the parking brake. Loosen the lug nuts before lifting the vehicle with the jack. Remember to secure it on jack stands for extra stability.

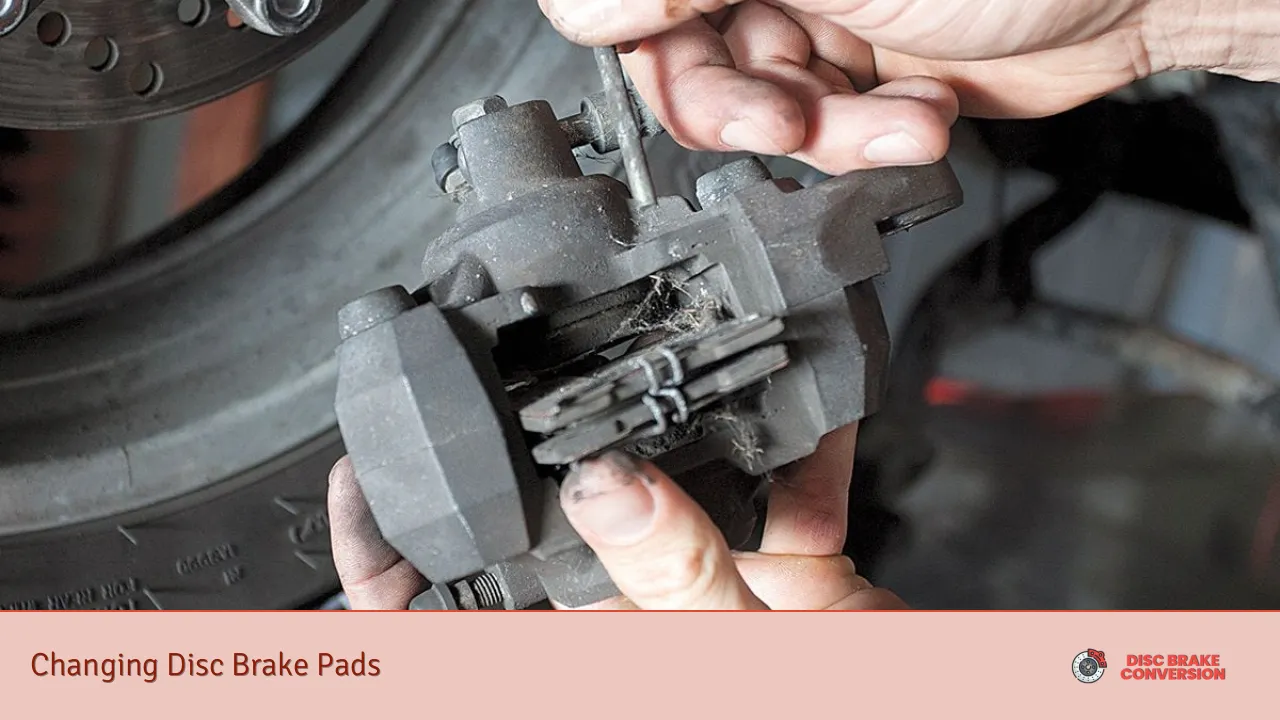

Now comes the fun part. Locate the brake caliper, which houses the brake pads. Remove the bolts securing the caliper and gently pry it off using a screwdriver. Take note of how the old brake pads fit inside the caliper. It’s like solving a puzzle! Next, compress the piston back into the caliper using the C-clamp, making room for the new, thicker pads.

Once that’s done, it’s time to place those shiny new brake pads into the caliper, just as the old ones were positioned. Double-check everything and then reattach the caliper to its rightful place, tightening the bolts securely. Finally, put your wheels back on, lower the jack, and give yourself a pat on the back. You’ve successfully changed your disc brake pads!

By mastering this skill, you’ve gained more than just mechanical know-how. You’ve empowered yourself with the ability to ensure your own safety on the road. So, go ahead, embrace the satisfaction of being a DIY hero, and enjoy those smooth, worry-free rides!

Revolutionizing Brake Maintenance: Innovative Techniques for Changing Disc Brake Pads

Are you tired of the hassle and high costs associated with brake maintenance? Well, get ready to be amazed because a revolution in brake maintenance is here! In this article, we will explore innovative techniques for changing disc brake pads that will not only save you time and money but also ensure your safety on the road.

Let’s face it, changing disc brake pads has always been a cumbersome task. But fret not, because advancements in technology have paved the way for revolutionary methods that simplify the process. One such technique is the use of quick-release mechanisms. These ingenious devices allow you to effortlessly remove and replace brake pads without the need for specialized tools or extensive mechanical knowledge. With just a few simple steps, you can have your brake pads changed in no time!

But wait, there’s more! Another groundbreaking advancement is the introduction of self-adjusting brake pads. Gone are the days of manual adjustments and constant monitoring. These innovative brake pads are equipped with sensors that automatically adjust the pad position as they wear down. This not only optimizes braking performance but also extends the lifespan of your brake pads, saving you money in the long run.

Now, you might be wondering about the durability and effectiveness of these new techniques. Rest assured, extensive testing and development have ensured that these innovations meet the highest standards of quality and reliability. Manufacturers have invested significant resources in research and development to deliver products that excel in both performance and safety.

So, why should you embrace these revolutionary techniques? The answer is simple: convenience, cost savings, and enhanced safety. By adopting these innovations, you can say goodbye to lengthy and expensive brake maintenance procedures. With quick-release mechanisms and self-adjusting brake pads, you’ll have peace of mind knowing that your brakes are operating at their best.

The world of brake maintenance is undergoing a remarkable transformation. Innovative techniques such as quick-release mechanisms and self-adjusting brake pads are revolutionizing the way we change disc brake pads. Embrace these advancements, and you’ll experience the convenience, cost savings, and safety benefits they offer. It’s time to say goodbye to the old ways and welcome a new era of brake maintenance!

Mastering the Art of Braking: Expert Tips and Tricks for Replacing Disc Brake Pads

When it comes to ensuring your vehicle’s safety, mastering the art of braking is essential. One crucial aspect of maintaining an efficient braking system is replacing disc brake pads regularly. In this article, we will provide you with expert tips and tricks to help you navigate through this process smoothly.

Firstly, let’s understand why disc brake pads need to be replaced. Over time, brake pads wear out due to constant friction against the rotors. This wear leads to reduced braking efficiency and potential damage to other components. By replacing the brake pads in a timely manner, you can maintain optimal braking performance and prevent costly repairs.

Now, let’s dive into the steps involved in replacing disc brake pads. Start by gathering the necessary tools: a lug wrench, a jack and jack stands, a C-clamp or brake piston tool, a wire brush, and of course, new brake pads specifically designed for your vehicle.

Begin by loosening the lug nuts on the wheel where you’ll be replacing the brake pads. Then, use the jack to lift the vehicle and secure it with jack stands for safety. With the wheel removed, locate the brake caliper, which houses the brake pads. Carefully remove the caliper bolts and slide out the old brake pads.

Before installing the new pads, take a moment to clean the caliper and rotor surface with a wire brush. This step ensures proper contact and maximizes braking performance. Insert the new brake pads into the caliper, making sure they fit snugly. Use a C-clamp or brake piston tool to compress the caliper piston if necessary.

Finally, reattach the caliper to its original position by tightening the bolts securely. Put the wheel back on, tighten the lug nuts, and lower the vehicle. Repeat these steps for each wheel requiring new brake pads.

Remember, practice makes perfect when it comes to brake pad replacement. If you’re unsure or uncomfortable performing this task yourself, it’s always best to consult a professional mechanic.

By mastering the art of braking and following these expert tips and tricks for replacing disc brake pads, you can ensure your vehicle’s safety and enjoy a smooth driving experience. So, don’t delay—take care of your brakes today and drive with confidence!

Unveiling the Future of Braking: Next-Generation Materials for Long-Lasting Disc Brake Pads

The world of braking is on the brink of a revolution, as engineers and innovators push the boundaries of technology to unveil the future of braking. Among the many advancements, one area that holds great promise is the development of next-generation materials for long-lasting disc brake pads. These cutting-edge materials are poised to leave a lasting impact on automotive safety and performance.

Imagine a brake pad that not only provides exceptional stopping power but also endures extended periods of use without losing its effectiveness. This is precisely what the next-generation materials aim to achieve. By harnessing the power of advanced composites and novel compounds, engineers are paving the way for a new era in braking efficiency.

One of the key challenges addressed by these materials is heat dissipation. Brake pads are subjected to immense frictional forces, resulting in high temperatures that can compromise their performance. However, with the introduction of innovative materials, this issue is being tackled head-on. These new materials possess superior thermal properties, allowing them to withstand extreme temperatures and maintain optimal braking performance even under demanding conditions.

Furthermore, longevity is another crucial aspect being addressed. Traditional brake pads often wear out relatively quickly, necessitating frequent replacements. This not only adds to the overall cost of vehicle ownership but also raises concerns about the environmental impact of disposing of worn-out pads. With next-generation materials, however, durability is greatly enhanced. These pads exhibit exceptional wear resistance, significantly extending their lifespan and reducing the need for frequent replacements.

Moreover, the evolution of braking materials goes beyond performance improvements. Considerations are also being given to environmental sustainability. As the world becomes more conscious of its ecological footprint, manufacturers are actively working towards developing eco-friendly brake pad materials. This means exploring alternatives to hazardous substances commonly found in traditional pads, such as asbestos and heavy metals. By opting for greener materials, the next generation of brake pads aims to strike a balance between superior performance and environmental responsibility.

The future of braking is indeed exciting, with next-generation materials leading the way towards long-lasting disc brake pads. These advancements promise enhanced heat dissipation, exceptional durability, and a conscious effort towards sustainability. As automotive technology continues to evolve, we can look forward to safer and more efficient braking systems that will shape the future of transportation.

From Novice to Pro: Step-by-Step Guide on Changing Disc Brake Pads Like a Mechanic

Are you tired of spending your hard-earned cash on costly mechanic visits just to change your disc brake pads? Well, fret no more! In this step-by-step guide, we will take you from a novice to a pro in no time, teaching you how to change disc brake pads like a seasoned mechanic. So grab your tools and let’s get started!

Step 1: Gather Your Tools

Before diving into the nitty-gritty of disc brake pad replacement, make sure you have all the necessary tools at hand. You’ll need a lug wrench, a jack, jack stands, a C-clamp, a socket set, a screwdriver, and, of course, new brake pads. Safety goggles and gloves are also recommended for protection.

Step 2: Prepare Your Vehicle

Ensure your vehicle is on a level surface and engage the parking brake. Loosen the lug nuts on the wheel where you’ll be replacing the brake pads. Lift the car using the jack and secure it with jack stands. Remove the lug nuts and take off the wheel.

Step 3: Remove the Caliper

Locate the caliper, which houses the brake pads. Using a socket or wrench, loosen the bolts holding the caliper in place. Once loose, slide the caliper out carefully, taking care not to damage the brake line.

Step 4: Replace the Brake Pads

With the caliper off, remove the old brake pads. Pay attention to how they are installed, as this will help when installing the new ones. Using a C-clamp, compress the piston back into the caliper to create space for the thicker new pads.

Step 5: Install the New Brake Pads

Apply a thin layer of brake lubricant to the back of the new brake pads. Insert them into the caliper, making sure they align correctly with the rotor. Slide the caliper back over the rotor and tighten the bolts securely.

Step 6: Put Everything Back Together

Double-check all connections and ensure everything is tightened properly. Put the wheel back on and hand-tighten the lug nuts. Lower the vehicle to the ground and use a torque wrench to tighten the lug nuts to the manufacturer’s specifications.

Congratulations! You’ve successfully changed your disc brake pads like a pro mechanic. Remember, practice makes perfect, so don’t be discouraged if it takes a few tries to get the hang of it. By following this step-by-step guide, you can save money and gain the satisfaction of maintaining your vehicle yourself. So go ahead, embrace the challenge and become a confident DIY mechanic!