Disc brakes are a crucial component of modern vehicle braking systems, providing superior stopping power and performance compared to traditional drum brakes. However, the concept of disc brakes “logging in” is not applicable, as they are mechanical devices without any login functionality. This article will explore the key aspects of disc brakes, their components, and how they function to ensure vehicle safety.

Disc brakes work by converting kinetic energy into heat energy through friction. When the brake pedal is pressed, hydraulic pressure forces brake pads against a rotating disc (rotor) attached to the wheel, creating friction that slows or stops the vehicle. This system offers several advantages over older drum brake designs, including better heat dissipation, more consistent performance, and easier maintenance.

| Component | Function |

|---|---|

| Rotor | Rotating disc attached to wheel |

| Caliper | Houses brake pads and pistons |

| Brake Pads | Create friction against rotor |

| Hydraulic System | Transfers force from pedal to caliper |

Disc Brake Components

The disc brake system consists of several key components that work together to provide effective braking. Understanding these parts is essential for proper maintenance and troubleshooting of brake-related issues.

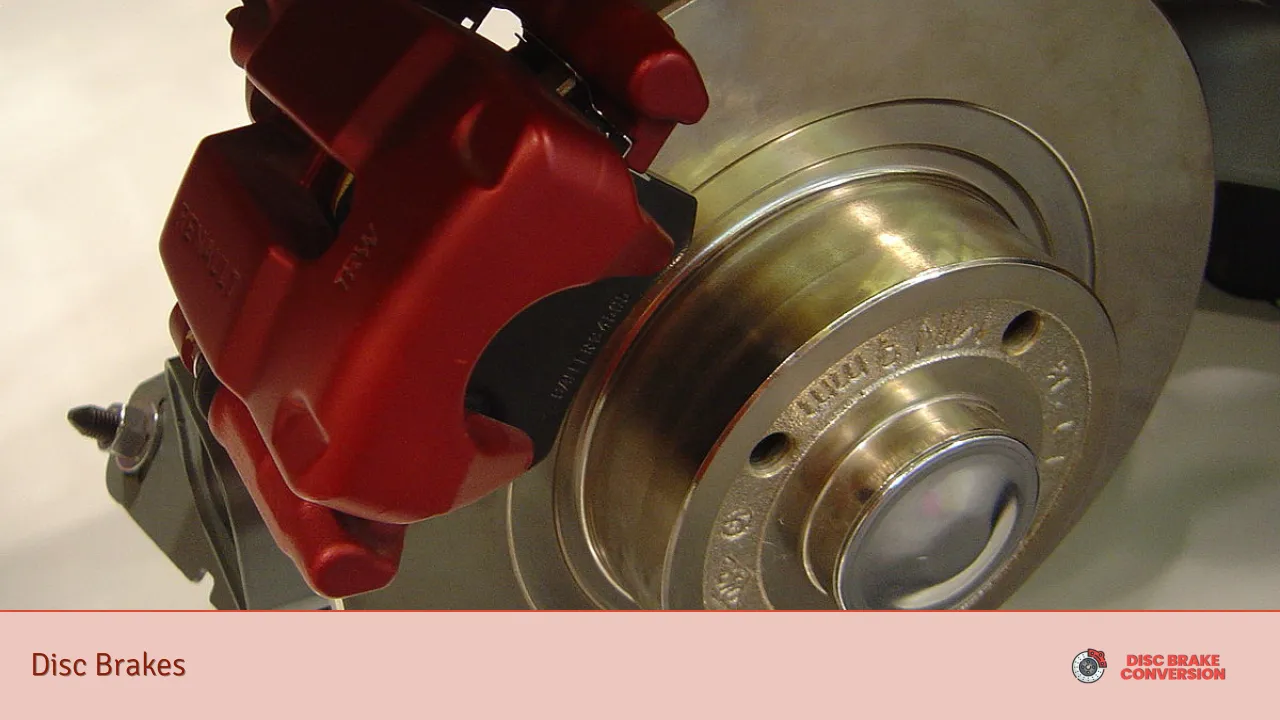

The rotor is a flat, circular disc attached to the wheel hub that rotates with the wheel. Typically made of cast iron or steel, rotors can also feature slots or drilling to enhance heat dissipation. The surface of the rotor provides the friction area for the brake pads.

The caliper is a clamp-like device that houses the brake pads and pistons. When hydraulic pressure is applied, the pistons in the caliper push the brake pads against the rotor. Calipers can be either floating or fixed designs, with floating calipers being more common in passenger vehicles due to their simpler construction and lower cost.

Brake pads are the friction material that presses against the rotor to create the braking force. Made from various compounds, including metallic, semi-metallic, and ceramic materials, brake pads are designed to withstand high temperatures and provide consistent performance. The choice of pad material can affect braking characteristics, noise levels, and durability.

The hydraulic system consists of the master cylinder, brake lines, and brake fluid. When the brake pedal is pressed, it activates the master cylinder, which pressurizes the brake fluid. This pressure is then transmitted through the brake lines to the calipers, causing the pistons to move and apply the brake pads to the rotor.

Disc Brake Operation

The operation of disc brakes relies on the principles of hydraulics and friction to effectively slow or stop a vehicle. When the driver presses the brake pedal, it initiates a series of events that result in the application of braking force to the wheels.

First, the brake pedal movement is translated into hydraulic pressure by the master cylinder. This pressure is then transmitted through the brake lines to the calipers at each wheel. As the pressure increases, it forces the pistons in the calipers to move outward, pushing the brake pads against the rotating rotor.

The friction between the brake pads and the rotor converts the vehicle’s kinetic energy into heat energy. This process slows the rotation of the rotor and, consequently, the wheel to which it is attached. The amount of braking force applied is proportional to the pressure exerted on the brake pedal, allowing for precise control of the vehicle’s deceleration.

One of the key advantages of disc brakes is their ability to dissipate heat quickly. As the rotor spins, it is exposed to air, which helps cool it down. Many rotors are also vented, featuring internal channels that further enhance heat dissipation. This design helps prevent brake fade, a condition where braking performance decreases due to overheating.

The self-adjusting nature of disc brakes is another important feature. As the brake pads wear down over time, the caliper pistons automatically extend further to maintain proper contact with the rotor. This ensures consistent braking performance and eliminates the need for manual adjustments, which were often required with older drum brake systems.

Maintenance and Troubleshooting

Proper maintenance of disc brakes is crucial for ensuring optimal performance and safety. Regular inspections and timely repairs can prevent many common issues and extend the lifespan of brake components.

One of the most important maintenance tasks is checking brake pad thickness. As brake pads wear down, they become thinner and eventually need replacement. Most vehicles have wear indicators that produce a squealing noise when the pads are nearing the end of their useful life. It’s generally recommended to replace brake pads when they reach about 3-4 mm in thickness.

Rotor condition should also be regularly assessed. Over time, rotors can become warped or develop uneven wear patterns, leading to pulsations in the brake pedal or steering wheel during braking. In some cases, rotors can be resurfaced to restore a smooth braking surface, but if they are too worn or damaged, replacement is necessary.

The hydraulic system requires attention as well. Brake fluid should be checked periodically and replaced according to the vehicle manufacturer’s recommendations. Old or contaminated brake fluid can lead to reduced braking performance and potentially damage internal components of the brake system.

Common disc brake problems and their solutions include:

- Squealing or squeaking: Often caused by worn brake pads or the presence of contaminants. Solution: Replace pads or clean brake components.

- Pulsating brake pedal: Usually indicates warped rotors. Solution: Resurface or replace rotors.

- Spongy brake pedal: May be due to air in the hydraulic system. Solution: Bleed the brakes to remove air bubbles.

- Pulling to one side during braking: Can be caused by uneven pad wear or a stuck caliper. Solution: Replace pads or repair/replace caliper.

- Brake drag: Often results from a seized caliper or incorrect pad installation. Solution: Repair or replace caliper, ensure proper pad fitment.

Regular brake inspections by a qualified technician can help identify these issues early and prevent more serious problems from developing. Additionally, adhering to the vehicle manufacturer’s recommended maintenance schedule can help ensure the longevity and reliability of the brake system.

FAQs About Disc Brakes

- How often should disc brakes be serviced?

Disc brakes should be inspected every 12,000 miles or annually, whichever comes first. - Can disc brakes be retrofitted to older vehicles?

Yes, many older vehicles can be upgraded to disc brakes, but it requires significant modifications. - Are ceramic brake pads better than metallic ones?

Ceramic pads generally produce less dust and noise but may be more expensive than metallic pads. - How long do disc brake rotors typically last?

Rotors can last anywhere from 30,000 to 70,000 miles, depending on driving habits and conditions. - Is it normal for disc brakes to make noise?

Some noise is normal, especially in wet conditions, but persistent squealing or grinding indicates a problem.