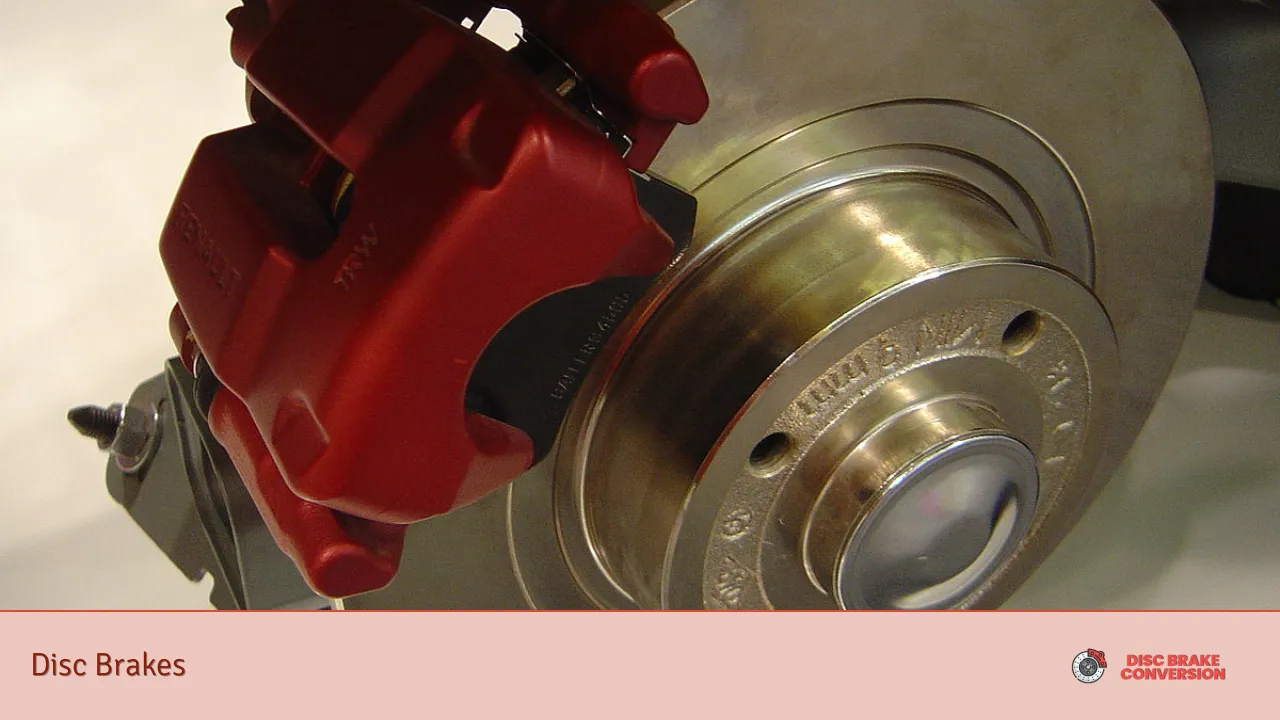

Disc brakes are a crucial component of modern vehicle braking systems, providing superior stopping power and performance compared to traditional drum brakes. These brakes use calipers to squeeze pairs of pads against a disc (also called a rotor) attached to the wheel hub, creating friction to slow or stop the vehicle. Disc brakes offer better heat dissipation, more consistent performance in various weather conditions, and improved overall braking efficiency.

The disc brake system consists of several key components working together to ensure reliable and effective braking. These include the brake rotor, brake pads, caliper, and hydraulic system. When the driver presses the brake pedal, hydraulic pressure is created, forcing the brake pads to clamp down on the spinning rotor, thus slowing the wheel’s rotation.

| Component | Function |

|---|---|

| Brake Rotor | Rotating disc attached to the wheel hub |

| Brake Pads | Friction material that presses against the rotor |

| Caliper | Houses the brake pads and pistons |

| Hydraulic System | Transfers force from brake pedal to caliper |

Types of Disc Brakes

There are two main types of disc brakes: floating calipers and fixed calipers. Each type has its own advantages and is suited for different vehicle applications.

Floating Calipers

Floating calipers, also known as sliding calipers, are the most common type used in passenger vehicles. They feature one or two pistons on the inboard side of the rotor. When the brakes are applied, the piston(s) push the inner brake pad against the rotor. The caliper then “floats” on sliding pins, bringing the outer pad into contact with the rotor.

Key features of floating calipers:

- More economical to produce

- Simpler design with fewer parts

- Easier to maintain and service

- Suitable for most passenger vehicles

Floating calipers are ideal for everyday driving conditions and provide reliable braking performance for most vehicles. Their simpler design makes them more cost-effective and easier to maintain, which is why they are widely used in the automotive industry.

Fixed Calipers

Fixed calipers, on the other hand, do not move relative to the rotor. They have pistons on both sides of the rotor and remain in a fixed position. When the brakes are applied, pistons on both sides push the brake pads against the rotor simultaneously.

Key features of fixed calipers:

- More rigid and stable design

- Better heat dissipation

- Improved brake pedal feel

- Typically used in high-performance vehicles

Fixed calipers offer superior braking performance and are often found in sports cars, luxury vehicles, and racing applications. Their rigid design provides better brake pedal feel and more consistent performance under extreme conditions. However, they are more complex and expensive to manufacture and maintain compared to floating calipers.

Advantages of Disc Brakes

Disc brakes offer several advantages over traditional drum brakes, making them the preferred choice for modern vehicles:

1. Superior Heat Dissipation: The open design of disc brakes allows for better cooling, reducing brake fade during prolonged or heavy braking.

2. Improved Wet Weather Performance: Water is easily shed from the disc surface, ensuring consistent braking even in wet conditions.

3. Self-Adjusting: Disc brakes automatically adjust for pad wear, maintaining consistent brake pedal feel over time.

4. Easier Maintenance: Brake pads are easily accessible and can be replaced without disassembling the entire brake assembly.

5. Better Modulation: Disc brakes provide more precise control over braking force, allowing for smoother stops.

6. Reduced Brake Fade: The superior heat dissipation of disc brakes results in more consistent performance during repeated heavy braking.

7. Lighter Weight: Disc brake systems are generally lighter than drum brake systems, contributing to better fuel efficiency and handling.

These advantages make disc brakes the standard choice for front brakes on most vehicles and increasingly common for rear brakes as well.

Disc Brake Components

Understanding the individual components of a disc brake system is crucial for proper maintenance and troubleshooting. Here’s a detailed look at each major component:

Brake Rotor

The brake rotor, also called a disc, is a circular metal disc attached to the wheel hub. It rotates with the wheel and serves as the friction surface for the brake pads. Rotors can be solid or ventilated, with ventilated rotors offering better cooling properties.

Key aspects of brake rotors:

- Made from cast iron, carbon-ceramic, or other high-performance materials

- May feature cross-drilled holes or slots for improved heat dissipation and water drainage

- Require periodic resurfacing or replacement to maintain optimal braking performance

Brake Pads

Brake pads are the friction material that presses against the rotor to create the stopping force. They are designed to wear down over time and require regular replacement.

Types of brake pad materials:

- Organic: Quieter operation but shorter lifespan

- Semi-metallic: Good heat transfer and durability

- Ceramic: Long-lasting and low dust production, but more expensive

Caliper

The caliper is the housing that holds the brake pads and pistons. It’s responsible for squeezing the pads against the rotor when the brakes are applied.

Caliper components:

- Piston(s): Push the brake pads against the rotor

- Slide pins (in floating calipers): Allow the caliper to move

- Dust boots: Protect the piston from contaminants

Hydraulic System

The hydraulic system transfers the force from the brake pedal to the caliper pistons. It consists of the following components:

- Master cylinder: Converts mechanical force from the brake pedal into hydraulic pressure

- Brake lines: Carry brake fluid from the master cylinder to the calipers

- Brake fluid: Incompressible fluid that transmits force through the system

Maintenance and Care

Proper maintenance of disc brakes is essential for ensuring optimal performance and safety. Here are some key maintenance tasks and considerations:

1. Regular Inspections: Visually inspect brake pads, rotors, and calipers for wear or damage at least every 12,000 miles or annually.

2. Brake Pad Replacement: Replace brake pads when they reach about 3-4mm thickness. Failing to do so can lead to rotor damage.

3. Rotor Resurfacing or Replacement: Resurface rotors if they are warped or have uneven wear. Replace if they are below the minimum thickness specified by the manufacturer.

4. Brake Fluid Changes: Flush and replace brake fluid every 2 years or 24,000 miles to prevent moisture buildup and maintain proper hydraulic function.

5. Caliper Maintenance: Lubricate caliper slide pins during brake pad replacement to ensure smooth operation.

6. Address Unusual Noises: Investigate and address any squealing, grinding, or other unusual noises promptly, as they may indicate wear or other issues.

7. Avoid Overheating: Allow brakes to cool after prolonged or heavy use, such as when driving down long hills or during performance driving.

By following these maintenance practices, you can ensure your disc brakes continue to perform optimally, providing reliable stopping power and safety for your vehicle.

FAQs About Disc Brakes

- How long do disc brakes typically last?

Disc brake rotors can last 30,000 to 70,000 miles, while pads typically need replacement every 30,000 to 50,000 miles, depending on driving conditions and habits. - Are disc brakes better than drum brakes?

Generally, yes. Disc brakes offer better stopping power, heat dissipation, and performance in wet conditions compared to drum brakes. - Can I upgrade from drum brakes to disc brakes?

It’s possible, but requires significant modifications to the wheel hub, brake lines, and possibly the master cylinder. Consult a professional for such upgrades. - Why do my disc brakes squeal?

Squealing can be caused by worn brake pads, glazed rotors, or the presence of contaminants. Regular maintenance can help prevent this issue. - How often should I have my disc brakes inspected?

It’s recommended to have your brakes inspected at least once a year or every 12,000 miles, whichever comes first.