Disc brakes are an essential component of modern vehicle braking systems, providing superior stopping power and performance compared to traditional drum brakes. These brakes operate on a simple yet effective principle, using friction to slow down or stop a vehicle’s wheels. Understanding how disc brakes work is crucial for anyone interested in automotive technology or looking to maintain their vehicle’s braking system.

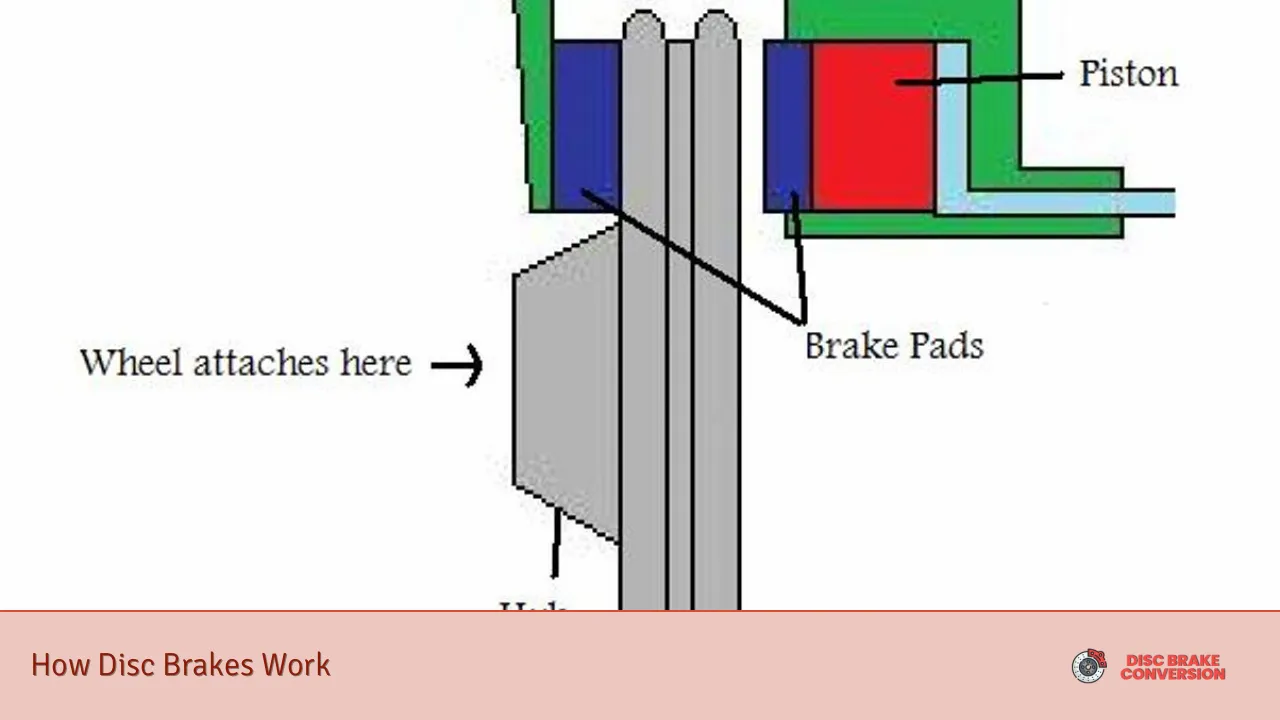

Disc brakes consist of several key components that work together to create the braking action. The main parts include the brake rotor, brake caliper, brake pads, and the hydraulic system. Each of these components plays a vital role in the overall function of the disc brake system.

| Component | Function |

|---|---|

| Brake Rotor | Rotating disc attached to the wheel |

| Brake Caliper | Houses brake pads and pistons |

| Brake Pads | Friction material that contacts the rotor |

| Hydraulic System | Transmits force from pedal to caliper |

The Brake Rotor

The brake rotor, also known as the brake disc, is a crucial component of the disc brake system. It is a flat, circular metal disc that is attached to the wheel hub and rotates with the wheel. The rotor serves as the primary surface against which the brake pads apply pressure to create friction and slow down the vehicle.

Rotors are typically made of cast iron due to its durability and heat-dissipation properties. However, some high-performance vehicles may use rotors made of carbon-ceramic composites for improved heat resistance and reduced weight. The design of the rotor can vary, with some featuring ventilated designs that incorporate internal vanes to improve cooling.

The surface of the rotor is machined to be smooth and flat, providing an even contact area for the brake pads. Over time, the rotor may develop grooves or become warped due to heat and wear, which can affect braking performance. Regular inspection and maintenance of the rotors are essential to ensure optimal braking efficiency.

Some rotors feature drilled holes or slotted designs on their surface. These modifications serve multiple purposes:

- Improved heat dissipation

- Better water dispersal in wet conditions

- Reduced brake fade during prolonged use

- Enhanced aesthetic appeal

It’s important to note that while these designs can offer benefits, they may also reduce the overall lifespan of the rotor due to increased stress points.

The Brake Caliper

The brake caliper is the component that houses the brake pads and the hydraulic pistons responsible for applying pressure to the pads. Calipers are mounted to the vehicle’s suspension system and straddle the brake rotor. There are two main types of calipers used in disc brake systems:

- Fixed calipers: These have pistons on both sides of the rotor and remain stationary during braking.

- Floating calipers: These have pistons on one side and move laterally to apply pressure on both sides of the rotor.

When the brake pedal is pressed, hydraulic pressure is sent to the caliper, causing the pistons to extend and push the brake pads against the rotor. The caliper’s design ensures that equal pressure is applied to both sides of the rotor, providing balanced braking force.

Modern calipers often incorporate features such as:

- Heat-resistant seals to prevent brake fluid leakage

- Anti-rattle clips to reduce noise

- Wear indicators to alert drivers when brake pads need replacement

The material used for calipers is typically aluminum or cast iron. Aluminum calipers are lighter and offer better heat dissipation, while cast iron calipers are more durable and cost-effective.

Brake Pads and Friction Material

Brake pads are the components that directly contact the rotor to create the friction necessary for braking. They consist of a steel backing plate with a layer of friction material bonded to it. The composition of this friction material can vary depending on the intended use and performance requirements of the vehicle.

Common types of friction materials include:

- Semi-metallic: Composed of metal fibers, fillers, and friction modifiers

- Ceramic: Made from ceramic fibers, nonferrous filler materials, and bonding agents

- Organic: Constructed from natural materials like rubber, glass, and Kevlar fibers

Each type of friction material offers different characteristics in terms of noise levels, dust production, heat resistance, and overall performance. The choice of brake pad material can significantly affect the braking feel and efficiency of a vehicle.

As the brake pads wear down over time, they need to be replaced to maintain optimal braking performance. Many brake pads include wear indicators that produce an audible squeal when the pad material has worn to a certain thickness, signaling the need for replacement.

The Hydraulic System

The hydraulic system is the means by which the force applied to the brake pedal is transmitted to the calipers. This system consists of several components:

- Master cylinder: Converts mechanical force from the pedal into hydraulic pressure

- Brake lines: Carry brake fluid from the master cylinder to the calipers

- Brake fluid: Incompressible fluid that transmits hydraulic pressure

- ABS module: (in vehicles equipped with Anti-lock Braking Systems) Modulates brake pressure to prevent wheel lockup

When the driver presses the brake pedal, it pushes a piston in the master cylinder, which pressurizes the brake fluid. This pressure is then transmitted through the brake lines to the calipers, causing the pistons to extend and apply the brake pads to the rotor.

The hydraulic system operates based on Pascal’s law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows for the multiplication of force, enabling a relatively small input force at the pedal to generate a much larger braking force at the wheels.

Advantages of Disc Brakes

Disc brakes offer several advantages over traditional drum brakes, which has led to their widespread adoption in modern vehicles:

- Superior heat dissipation: The exposed design of disc brakes allows for better cooling, reducing brake fade during prolonged use.

- Improved wet-weather performance: Water is easily shed from the disc surface, maintaining braking efficiency in wet conditions.

- Self-adjusting: Disc brakes automatically adjust for pad wear, maintaining consistent pedal feel over time.

- Easier maintenance: Brake pads are easily accessible for inspection and replacement.

- Better modulation: Disc brakes offer more precise control over braking force, improving overall vehicle handling.

These advantages make disc brakes the preferred choice for most modern vehicles, especially in high-performance applications where consistent, powerful braking is crucial.

FAQs About How Disc Brakes Work

- How often should disc brakes be serviced?

Disc brakes should be inspected every 12,000 miles or annually, with pad replacement typically needed every 30,000 to 70,000 miles depending on driving habits. - Can disc brakes be retrofitted to older vehicles with drum brakes?

Yes, many older vehicles can be upgraded to disc brakes, but it often requires additional modifications to the suspension and hydraulic systems. - Are ceramic brake pads better than semi-metallic ones?

Ceramic pads generally produce less dust and noise but may not perform as well under extreme heat compared to semi-metallic pads. - How do I know if my disc brakes need replacement?

Signs include squealing noises, reduced braking performance, vibration when braking, and visible wear on the rotors or pads. - Do electric vehicles use different disc brakes than conventional cars?

While the basic principle is the same, electric vehicles often use regenerative braking in conjunction with disc brakes, which can extend brake life.