Disc brakes are a crucial component of modern vehicle safety systems, providing reliable and efficient stopping power. These brakes operate on a simple yet effective principle, using friction to slow down or stop a vehicle’s wheels. Unlike drum brakes, which use internal shoes to press against the inside of a drum, disc brakes use pads to clamp down on a rotor attached to the wheel.

The disc brake system consists of several key components working together to bring a vehicle to a stop. These include the brake rotor, brake pads, caliper, and hydraulic system. When a driver presses the brake pedal, it initiates a chain reaction that ultimately results in the vehicle slowing down or coming to a complete stop.

Let’s take a closer look at the main components of a disc brake system and how they function together to provide effective braking performance.

| Component | Function |

|---|---|

| Brake Rotor | Rotating disc attached to the wheel |

| Brake Pads | Friction material that clamps onto the rotor |

| Caliper | Houses the brake pads and pistons |

| Hydraulic System | Transmits force from pedal to caliper |

Disc Brake Components

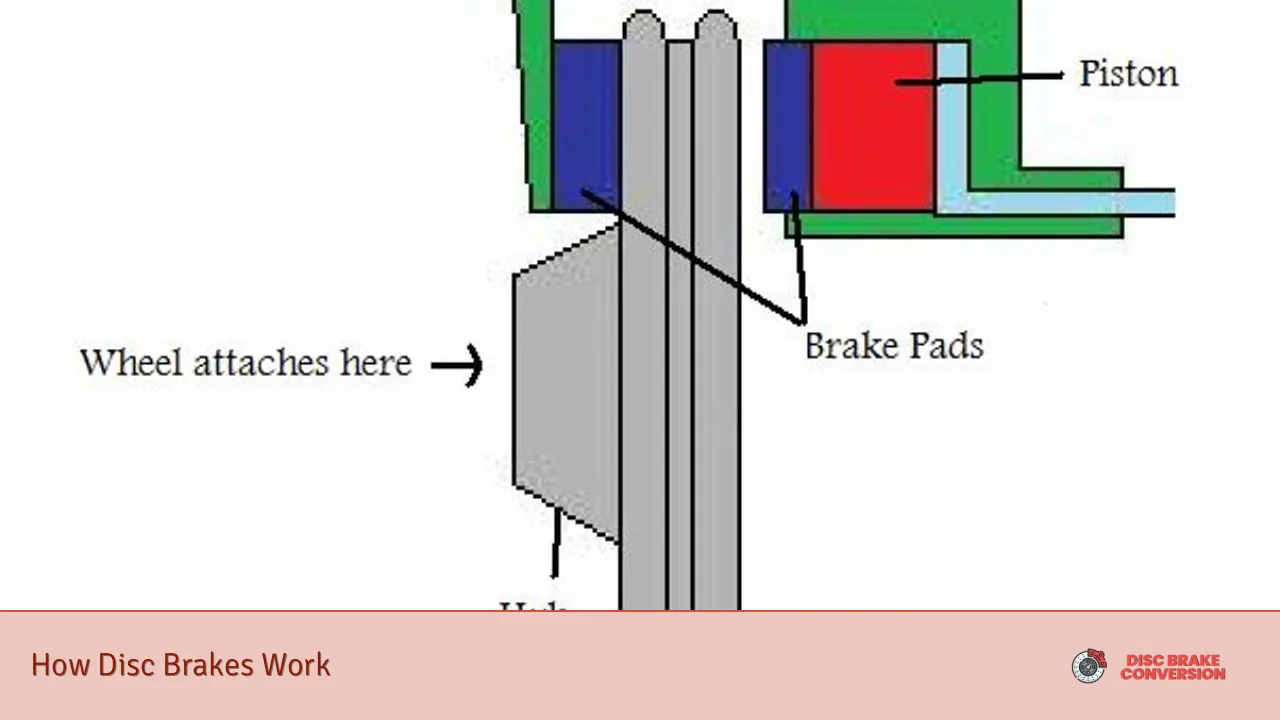

The disc brake system relies on several key components to function effectively. Understanding these parts is essential to comprehending how disc brakes work.

Brake Rotor

The brake rotor, also known as the disc, is a crucial component of the disc brake system. It’s a flat, circular piece of metal attached to the wheel hub and rotates with the wheel. Rotors are typically made of cast iron or carbon-ceramic materials, chosen for their ability to withstand high temperatures and resist wear.

Rotors come in two main designs:

- Solid rotors: A single piece of metal with a smooth surface

- Vented rotors: Two discs connected by internal vanes for improved cooling

The rotor’s surface is where the brake pads make contact to create friction and slow down the vehicle. Over time, rotors can become worn or warped, requiring resurfacing or replacement to maintain optimal braking performance.

Brake Pads

Brake pads are the friction material that presses against the rotor to create the stopping force. They’re designed to withstand high temperatures and pressures while providing consistent braking performance. Brake pads are typically made of a combination of materials, including:

- Metal fibers

- Ceramic compounds

- Organic materials

- Kevlar

The choice of brake pad material can affect braking performance, noise levels, and durability. High-performance vehicles often use metallic or ceramic pads for improved heat resistance and stopping power.

Caliper

The caliper is a clamp-like device that houses the brake pads and pistons. It’s mounted over the rotor and connected to the vehicle’s suspension system. Calipers come in two main types:

- Fixed calipers: Mounted in a fixed position with pistons on both sides

- Floating calipers: Move laterally and have pistons on only one side

When hydraulic pressure is applied, the caliper’s pistons push the brake pads against the rotor, creating friction and slowing the wheel’s rotation.

Hydraulic System

The hydraulic system is responsible for transmitting the force from the brake pedal to the calipers. It consists of:

- Master cylinder

- Brake lines

- Brake fluid

When the driver presses the brake pedal, it activates the master cylinder, which pressurizes the brake fluid. This pressure is then transmitted through the brake lines to the calipers, causing the pistons to extend and push the brake pads against the rotor.

How Disc Brakes Function

Now that we understand the components, let’s examine how disc brakes work in action. The process begins when the driver presses the brake pedal and ends with the vehicle slowing down or stopping completely.

1. Pedal Activation: When the driver presses the brake pedal, it applies force to the master cylinder.

2. Hydraulic Pressure: The master cylinder converts this mechanical force into hydraulic pressure within the brake lines.

3. Caliper Activation: The pressurized brake fluid travels through the brake lines to the calipers.

4. Piston Extension: The hydraulic pressure causes the pistons within the calipers to extend.

5. Pad Contact: The extended pistons push the brake pads against the spinning rotor.

6. Friction Generation: As the brake pads press against the rotor, they create friction, converting the vehicle’s kinetic energy into heat.

7. Vehicle Deceleration: This friction slows down the rotation of the rotor and, consequently, the wheel, causing the vehicle to decelerate.

8. Heat Dissipation: The heat generated during this process is dissipated by the rotor, often aided by vented designs or cooling fins.

The entire process happens almost instantaneously, providing drivers with responsive and reliable braking performance.

Advantages of Disc Brakes

Disc brakes offer several advantages over traditional drum brakes, which is why they’ve become the standard in modern vehicles, especially for front wheels where most of the braking force is applied.

Superior Heat Dissipation

One of the most significant advantages of disc brakes is their ability to dissipate heat effectively. The open design of the rotor allows for better airflow, which helps cool the braking system more quickly. This improved heat dissipation results in:

- Reduced brake fade: Brake fade occurs when brakes overheat and lose effectiveness. Disc brakes are less prone to this issue.

- Consistent performance: Better cooling means more consistent braking performance, even under heavy use.

- Longer component life: Lower operating temperatures can extend the life of brake pads and rotors.

Improved Stopping Power

Disc brakes generally provide better stopping power compared to drum brakes. This is due to several factors:

- Larger contact area: The flat surface of the rotor provides a larger area for the brake pads to grip.

- Linear force application: The direct application of force from the pads to the rotor is more efficient than the shoe-to-drum contact in drum brakes.

- Self-adjusting mechanism: Many disc brake systems automatically adjust for pad wear, ensuring consistent performance.

Better Performance in Wet Conditions

Disc brakes perform better in wet conditions compared to drum brakes. The open design allows water to be easily shed from the rotor surface, reducing the risk of hydroplaning and maintaining braking effectiveness. In contrast, water can become trapped inside drum brakes, temporarily reducing their efficiency.

Easier Maintenance and Inspection

Disc brakes are generally easier to maintain and inspect than drum brakes. The open design allows for:

- Visual inspection: Brake pad wear can often be checked without removing the wheel.

- Simpler pad replacement: Changing brake pads is typically a straightforward process.

- Easier cleaning: The exposed components can be cleaned more easily, reducing the buildup of brake dust and debris.

Maintenance and Care

Proper maintenance is crucial for ensuring the longevity and effectiveness of disc brakes. Here are some key maintenance tasks and considerations:

Regular Inspections

- Visual checks: Regularly inspect brake pads for wear. Many vehicles have a small window in the caliper for this purpose.

- Rotor condition: Check rotors for scoring, warping, or uneven wear.

- Fluid levels: Maintain proper brake fluid levels and check for leaks.

Brake Pad Replacement

- Replace brake pads when they reach the manufacturer’s recommended minimum thickness.

- Always replace pads in pairs (both wheels on the same axle) to ensure even braking performance.

Rotor Maintenance

- Resurfacing: Rotors may need to be resurfaced if they’re warped or have minor surface imperfections.

- Replacement: Severely worn or damaged rotors should be replaced entirely.

System Bleeding

- Periodically bleed the brake system to remove air bubbles, which can reduce braking efficiency.

- Follow the manufacturer’s recommended schedule for brake fluid replacement.

Warning Signs

Be aware of warning signs that indicate potential brake issues:

- Squealing or grinding noises

- Vibration in the brake pedal

- Reduced braking performance

- Pulling to one side when braking

Addressing these issues promptly can prevent more serious problems and ensure your vehicle’s braking system remains in top condition.

FAQs About How Disc Brakes Work

- How long do disc brakes typically last?

Disc brake pads usually last between 30,000 to 70,000 miles, depending on driving habits and conditions. - Are disc brakes better than drum brakes?

Disc brakes generally offer better performance, especially in wet conditions, and are easier to maintain than drum brakes. - Can I replace disc brake pads myself?

With proper tools and knowledge, replacing disc brake pads can be a DIY task, but professional installation is recommended for safety. - How often should disc brakes be serviced?

Disc brakes should be inspected every 12,000 miles or annually, whichever comes first, and serviced as needed based on wear. - What causes disc brakes to squeal?

Squealing can be caused by worn brake pads, glazed rotors, or the presence of dirt and debris in the braking system.