Disc brakes are a crucial component of modern automotive braking systems, providing reliable and efficient stopping power. Understanding how disc brakes function can enhance your knowledge of vehicle safety and maintenance. This article will explore the components, operation, advantages, and common issues associated with disc brakes in cars.

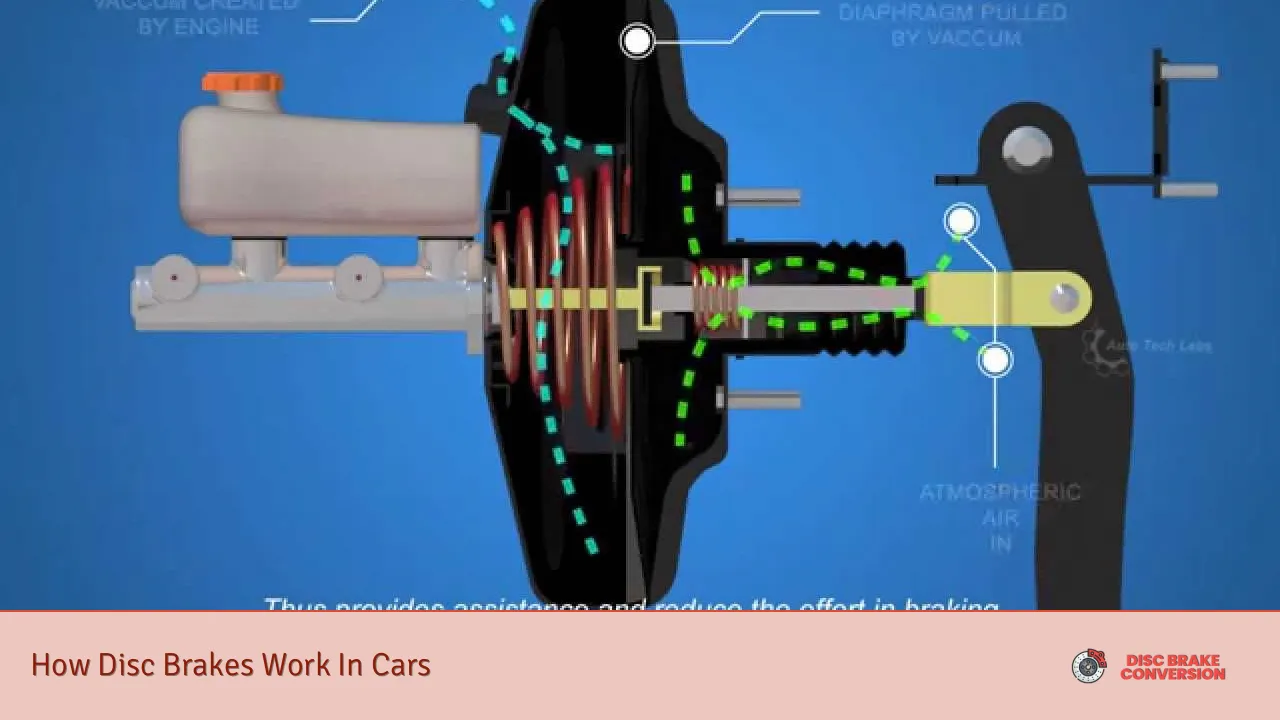

Disc brakes operate using a straightforward yet effective mechanism. When the brake pedal is pressed, hydraulic fluid is sent from the master cylinder to the brake calipers. The calipers then squeeze the brake pads against a rotating disc (or rotor), creating friction that slows down the vehicle. This process converts kinetic energy into heat, which is dissipated through the rotor. The design of disc brakes allows for better cooling compared to traditional drum brakes, making them less prone to overheating and brake fade.

The following table summarizes key components of a disc brake system:

| Component | Description |

|---|---|

| Brake Rotor | The disc that rotates with the wheel and provides a surface for the brake pads to clamp onto. |

| Brake Caliper | Houses the brake pads and pistons; applies pressure to the pads when braking. |

| Brake Pads | Friction material that presses against the rotor to create stopping power. |

| Master Cylinder | Generates hydraulic pressure when the brake pedal is pressed. |

| Hydraulic Lines | Transport brake fluid from the master cylinder to the calipers. |

Key Components of Disc Brakes

Understanding how disc brakes work requires familiarity with their essential components. Each part plays a vital role in ensuring effective braking performance.

- Brake Rotor: The rotor is typically made of cast iron or composite materials, designed to withstand high temperatures generated during braking. It rotates with the wheel and provides a surface for friction against the brake pads.

- Brake Caliper: The caliper houses one or more pistons that apply pressure to the brake pads. When hydraulic fluid enters the caliper, it pushes the pistons outward, forcing the pads against the rotor.

- Brake Pads: These are made from various friction materials that generate heat and friction when pressed against the rotor. Brake pads are designed to wear evenly, providing consistent performance over time.

- Master Cylinder: This component converts mechanical force from the brake pedal into hydraulic pressure. When you press down on the pedal, it forces brake fluid into the hydraulic lines.

- Hydraulic Lines: These flexible tubes carry brake fluid from the master cylinder to each caliper. They must be in good condition to ensure proper hydraulic pressure is maintained.

The interaction between these components is crucial for effective braking. When you press the brake pedal, hydraulic pressure builds up in the master cylinder, pushing fluid through the lines into each caliper. This action activates the pistons within the calipers, which then squeeze the brake pads against the rotor.

How Disc Brakes Operate

The operation of disc brakes is based on fundamental principles of physics and hydraulics. Here’s a step-by-step breakdown of how they work:

1. Pressing the Brake Pedal: When you apply pressure to the brake pedal, it activates a lever connected to the master cylinder.

2. Generating Hydraulic Pressure: The master cylinder converts this mechanical force into hydraulic pressure by pushing brake fluid through its outlet.

3. Activating Calipers: The pressurized fluid travels through hydraulic lines to each brake caliper, where it enters small cylinders containing pistons.

4. Pushing Brake Pads Against Rotor: The hydraulic pressure forces these pistons outward, causing them to push against the brake pads. The pads then clamp onto both sides of the rotating rotor.

5. Creating Friction: As the pads press against the rotor, they create friction that slows down or stops its rotation, effectively reducing vehicle speed.

6. Heat Dissipation: The friction generates heat, which is dissipated through vents or drilled holes in many modern rotors to prevent overheating and maintain performance.

This entire process occurs rapidly and efficiently, allowing drivers to stop their vehicles safely in various conditions.

Advantages of Disc Brakes

Disc brakes offer several advantages over traditional drum brakes, making them a popular choice for modern vehicles:

- Better Cooling: Disc brakes have a greater surface area exposed to air than drum brakes, allowing for more efficient heat dissipation. This helps prevent overheating during prolonged braking.

- Consistent Performance: Disc brakes provide reliable stopping power under different conditions, including wet or dry surfaces. They recover quickly from immersion in water compared to drum brakes.

- Reduced Brake Fade: Due to their superior cooling capabilities, disc brakes experience less fade during heavy use, maintaining their effectiveness even under demanding conditions.

- Easier Maintenance: Brake pads on disc systems are typically easier to inspect and replace than those on drum systems. This accessibility simplifies routine maintenance tasks for vehicle owners.

- Improved Stopping Power: Disc brakes generally offer shorter stopping distances due to their ability to generate more friction and dissipate heat effectively.

These benefits contribute significantly to vehicle safety and performance, making disc brakes an essential feature in today’s automotive designs.

Common Issues with Disc Brakes

While disc brakes are generally reliable, they can encounter issues that affect their performance:

- Worn Brake Pads: Over time, brake pads wear down due to friction with the rotor. If not replaced promptly, they can lead to reduced braking efficiency or damage to other components.

- Warped Rotors: Excessive heat can cause rotors to warp, leading to vibrations during braking or uneven wear on brake pads. Regular inspections can help identify this issue early.

- Leaking Calipers: A damaged caliper can leak hydraulic fluid, resulting in decreased braking power or a soft pedal feel when pressing down on the brake pedal.

- Contaminated Brake Fluid: Moisture or debris in brake fluid can affect its performance and lead to corrosion within hydraulic components. Regularly flushing and replacing brake fluid is essential for optimal function.

- Air in Hydraulic Lines: Air bubbles trapped in hydraulic lines can cause spongy or unresponsive braking. Bleeding the system removes air and restores proper function.

Awareness of these common problems allows vehicle owners to take proactive measures in maintaining their braking systems and ensuring safety on the road.

FAQs About How Disc Brakes Work In Cars

- What are disc brakes used for?

Disc brakes are primarily used for slowing down or stopping vehicles by creating friction against rotating discs. - How do I know if my disc brakes need replacing?

If you hear squeaking noises or experience reduced braking efficiency, it may be time to replace your disc brakes. - Can I replace my own disc brakes?

Yes, many car owners can replace their own disc brakes with proper tools and knowledge about their vehicle’s braking system. - What causes disc brakes to fade?

Excessive heat generated during prolonged braking can cause disc brakes to fade, reducing their effectiveness. - How often should I check my disc brakes?

You should have your disc brakes inspected at least once a year or whenever you notice any changes in performance.

Understanding how disc brakes work enhances your knowledge of automotive safety and maintenance practices. By familiarizing yourself with their components and operation, you can ensure your vehicle remains safe on the road while also addressing any potential issues proactively.