Disc brake calipers are a crucial component of modern automotive braking systems, responsible for converting hydraulic pressure into mechanical force to slow down or stop a vehicle. Understanding how they operate can help vehicle owners maintain their brakes effectively and ensure safety on the road.

When the driver presses the brake pedal, hydraulic fluid is pushed from the master cylinder to the brake calipers. Inside each caliper, pistons are activated by this hydraulic pressure, pushing the brake pads against the spinning brake rotor. This action creates friction, which slows down the wheels and ultimately brings the vehicle to a stop.

The operation of disc brake calipers can be broken down into several key components and processes that work together seamlessly.

| Component | Function |

|---|---|

| Brake Caliper | Houses brake pads and pistons; applies pressure to pads against rotor. |

| Pistons | Convert hydraulic pressure into mechanical force. |

| Brake Pads | Create friction with the rotor to slow down the vehicle. |

| Brake Rotor | Spins with the wheel; is squeezed by pads to create stopping power. |

The Structure of Brake Calipers

Brake calipers consist of several essential parts that work together to facilitate braking. Each caliper typically includes:

- Housing: The outer casing that holds all components together.

- Pistons: Cylindrical components that move outward when hydraulic pressure is applied.

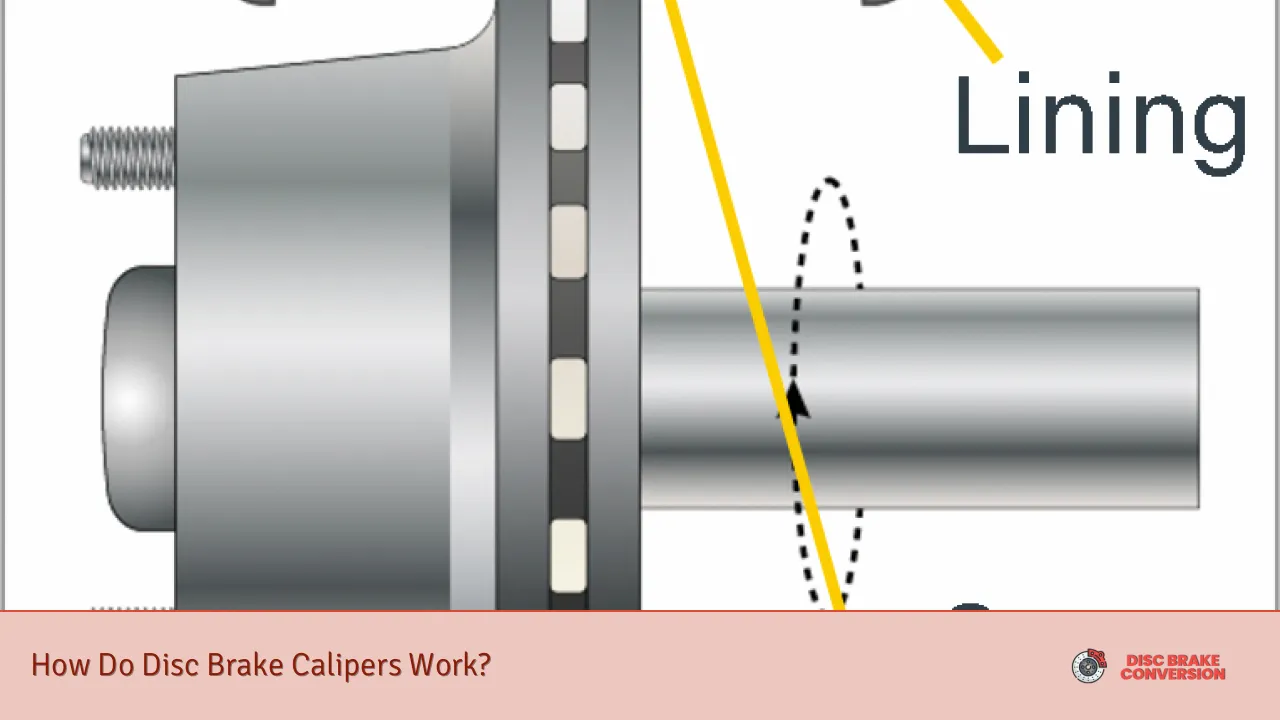

- Brake Pads: Friction material that presses against the rotor.

- Seals: Prevent fluid leakage and keep contaminants out.

There are two main types of brake calipers: floating and fixed.

Floating Calipers

Floating calipers have one or two pistons located on one side of the rotor. When hydraulic pressure is applied, these pistons push the inner brake pad against the rotor. As this happens, the caliper itself moves slightly to pull the outer pad into contact with the rotor. This design allows for even wear on both pads and is commonly used in many vehicles due to its simplicity and effectiveness.

Fixed Calipers

Fixed calipers, on the other hand, have pistons on both sides of the rotor. They do not move; instead, they apply equal pressure from both sides simultaneously. This design offers improved braking performance as it distributes force evenly across both pads, allowing for more effective stopping power. However, fixed calipers are generally more complex and expensive than floating calipers.

How Brake Calipers Function

The operation of brake calipers involves several steps:

1. Pressing the Brake Pedal: When a driver presses down on the brake pedal, it activates the master cylinder.

2. Hydraulic Fluid Movement: The master cylinder sends pressurized hydraulic fluid through brake lines to the caliper.

3. Piston Activation: The hydraulic pressure forces pistons within the caliper to move outward.

4. Pad Engagement: As pistons move, they push against the brake pads, which then squeeze against the rotating brake rotor.

5. Friction Creation: The contact between the pads and rotor generates friction, which slows down or stops wheel rotation.

6. Release of Pressure: When the driver releases the brake pedal, hydraulic pressure decreases, allowing springs or seals to retract the pistons and disengage the pads from the rotor.

This entire process occurs rapidly and repeatedly during driving conditions, ensuring effective braking when needed.

Maintenance of Brake Calipers

To ensure optimal performance and longevity of brake calipers, regular maintenance is essential. Here are some key practices:

- Inspect for Leaks: Check around calipers for any signs of fluid leaks which could indicate seal failure.

- Monitor Pad Wear: Regularly inspect brake pads for wear; replace them when they become too thin.

- Clean Components: Keep calipers clean from dirt and debris to prevent sticking or uneven wear.

- Check Hydraulic Fluid Levels: Ensure that brake fluid levels are adequate as low levels can affect braking performance.

- Look for Corrosion: Inspect metal components for rust or corrosion that may compromise structural integrity.

By following these maintenance practices, drivers can help prevent costly repairs and ensure their braking system functions effectively.

Common Problems with Brake Calipers

Brake calipers can experience several issues over time due to wear and tear or improper maintenance:

- Leaking Fluid: A common sign of failure is visible brake fluid leaking from around the caliper seals.

- Sticking Piston: If a piston becomes stuck due to dirt or corrosion, it may not retract properly after braking, causing uneven pad wear and reduced braking efficiency.

- Uneven Wear: If one pad wears significantly faster than another, it could indicate a problem with how pressure is distributed across the caliper.

- Noise During Braking: Squeaking or grinding noises can suggest worn pads or issues with how they engage with the rotor.

Addressing these problems promptly can prevent further damage to other braking components and maintain vehicle safety.

FAQs About Disc Brake Calipers

- What are disc brake calipers?

Disc brake calipers are components that house brake pads and pistons, applying pressure against rotors to slow down or stop vehicles. - How do floating and fixed calipers differ?

Floating calipers have pistons on one side and move during braking; fixed calipers have pistons on both sides and remain stationary. - What causes brake caliper failure?

Common causes include fluid leaks, corrosion, sticking pistons, and uneven pad wear. - How often should I inspect my brake calipers?

It’s advisable to inspect your brake calipers at least once a year or whenever you replace your brake pads. - Can I drive with a faulty brake caliper?

No, driving with a faulty brake caliper can compromise safety and lead to further damage in your braking system.

Understanding how disc brake calipers work is essential for maintaining vehicle safety and performance. By recognizing their function, structure, operation, maintenance needs, and potential issues, drivers can ensure their braking systems remain reliable over time.