Disc brakes are a crucial component of modern vehicle braking systems, providing efficient and reliable stopping power. These brakes work by converting the kinetic energy of a moving vehicle into heat energy through friction, ultimately bringing the vehicle to a stop. The disc brake system consists of several key components that work together to achieve this goal.

At the heart of the disc brake system is the rotor, a flat, circular metal disc attached to the wheel hub. As the wheel rotates, so does the rotor. When the driver applies pressure to the brake pedal, hydraulic fluid is forced through the brake lines, activating the brake caliper. The caliper then squeezes the brake pads against both sides of the spinning rotor, creating friction and slowing down the wheel’s rotation.

Let’s take a closer look at the main components of a disc brake system and how they function together:

| Component | Function |

|---|---|

| Rotor | Rotating disc attached to wheel hub |

| Caliper | Houses brake pads and pistons |

| Brake Pads | Friction material that contacts rotor |

| Hydraulic System | Transfers force from pedal to caliper |

Disc Brake Components and Their Functions

The disc brake system comprises several essential components that work in harmony to provide effective braking. Understanding these components and their roles is crucial for grasping how disc brakes function.

Rotor: The rotor, also known as the disc, is a flat, circular piece of metal attached to the wheel hub. It rotates along with the wheel and serves as the surface against which the brake pads apply pressure. Rotors are typically made of cast iron or steel, though some high-performance vehicles may use carbon-ceramic rotors for improved heat dissipation and reduced weight. The rotor’s design often includes ventilation channels or drilled holes to help dissipate heat generated during braking.

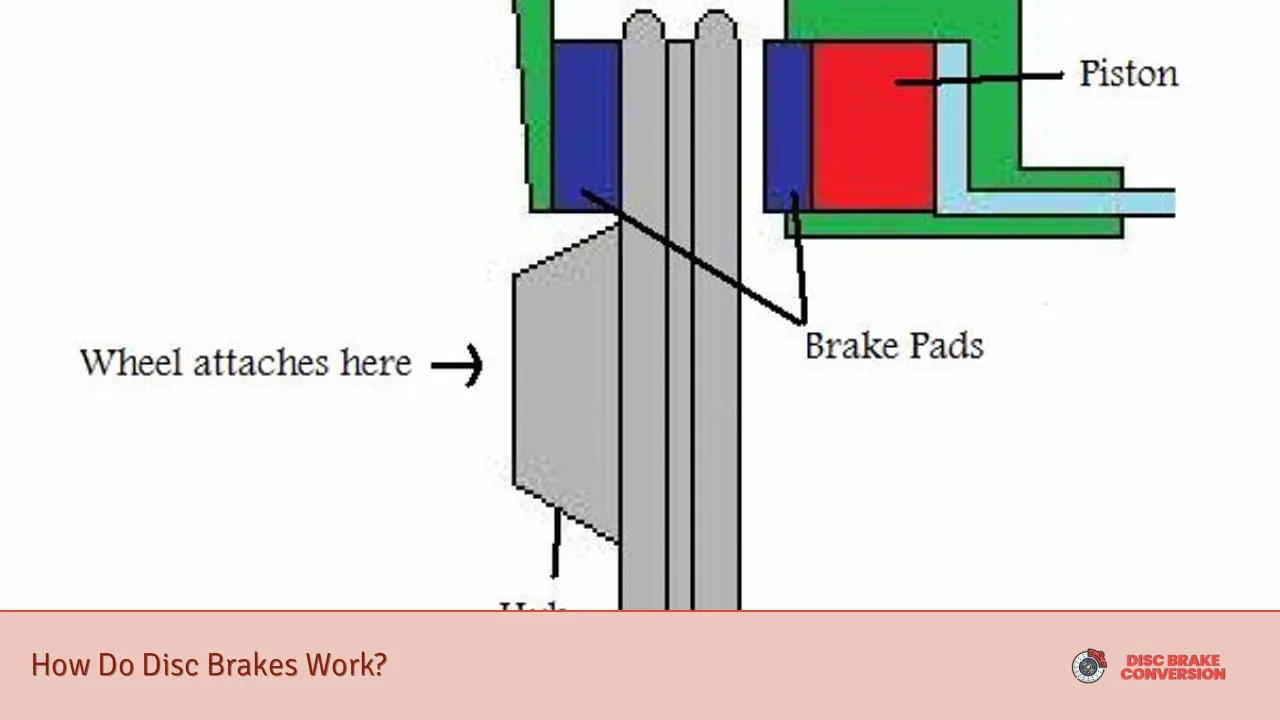

Caliper: The caliper is a clamp-like device that houses the brake pads and pistons. It’s mounted over the rotor and is responsible for squeezing the brake pads against the rotor when the brakes are applied. There are two main types of calipers: fixed and floating. Fixed calipers have pistons on both sides of the rotor and don’t move relative to the rotor. Floating calipers, more common in passenger vehicles, have pistons on one side and slide on pins to apply pressure to both sides of the rotor.

Brake Pads: Brake pads are the friction material that comes into direct contact with the rotor. They’re designed to withstand high temperatures and provide consistent braking performance. Brake pads are typically made from a combination of materials, including metals, ceramics, and organic compounds. The composition of brake pads affects their performance characteristics, such as stopping power, noise levels, and durability.

Hydraulic System: The hydraulic system is responsible for transferring the force applied to the brake pedal to the caliper pistons. It consists of the master cylinder, brake lines, and brake fluid. When the driver presses the brake pedal, it activates the master cylinder, which pressurizes the brake fluid. This pressurized fluid travels through the brake lines to the calipers, pushing the pistons outward and applying force to the brake pads.

How Disc Brakes Operate

The operation of disc brakes involves a series of steps that occur rapidly when the driver applies pressure to the brake pedal. Understanding this process helps explain why disc brakes are so effective at slowing down or stopping a vehicle.

1. Pedal Application: The process begins when the driver presses the brake pedal. This action applies force to the master cylinder located under the hood of the vehicle.

2. Hydraulic Pressure: The master cylinder converts the mechanical force from the pedal into hydraulic pressure. It pushes brake fluid through the brake lines, creating a pressurized system.

3. Caliper Activation: The pressurized brake fluid reaches the brake calipers at each wheel. In a floating caliper design, the fluid pushes a piston (or pistons) outward.

4. Pad Contact: As the piston extends, it presses the inner brake pad against the rotor. Simultaneously, the caliper slides on its mounting pins, pulling the outer pad into contact with the opposite side of the rotor.

5. Friction and Heat Generation: The brake pads squeeze the spinning rotor, creating friction. This friction converts the kinetic energy of the moving vehicle into heat energy, slowing down the rotation of the wheel.

6. Heat Dissipation: The heat generated during braking is quickly dissipated through the rotor. Vented rotors with internal fins or drilled/slotted designs help improve heat dissipation.

7. Vehicle Deceleration: As all four wheels experience this braking action simultaneously, the vehicle slows down or comes to a complete stop, depending on the amount of pressure applied to the brake pedal.

8. Brake Release: When the driver releases the brake pedal, the hydraulic pressure decreases. Springs in the caliper retract the piston and pads, allowing the rotor to spin freely again.

Advantages of Disc Brakes

Disc brakes offer several significant advantages over traditional drum brakes, which is why they’ve become the standard in modern vehicles, especially for front wheels where the majority of braking force is applied.

Superior Heat Dissipation: One of the most significant advantages of disc brakes is their ability to dissipate heat quickly. The exposed rotor allows for better airflow, which helps cool the braking system more efficiently than drum brakes. This improved heat dissipation reduces the risk of brake fade, a condition where brakes lose effectiveness due to overheating.

Consistent Performance: Disc brakes provide more consistent performance in various conditions. They’re less susceptible to water and debris, which can significantly affect the performance of drum brakes. The self-cleaning action of disc brakes, where centrifugal force throws off water and debris, helps maintain consistent braking power.

Better Modulation: Disc brakes offer superior brake modulation, allowing drivers to apply braking force more precisely. This improved control is particularly beneficial in emergency braking situations or when driving in challenging conditions.

Reduced Brake Fade: Due to their superior heat dissipation, disc brakes are less prone to brake fade during prolonged or repeated heavy braking. This makes them ideal for performance driving or towing applications where consistent braking power is crucial.

Easier Maintenance: Disc brakes are generally easier to inspect and maintain than drum brakes. Brake pad replacement is typically a simpler process, and wear is more easily visible without disassembly.

Self-Adjusting: Most disc brake systems are self-adjusting, maintaining proper clearance between the pads and rotor as the pads wear. This eliminates the need for manual adjustments and ensures consistent brake pedal feel over time.

Maintenance and Care of Disc Brakes

Proper maintenance of disc brakes is essential for ensuring optimal performance, safety, and longevity of the braking system. Here are some key aspects of disc brake maintenance and care:

Regular Inspections: Visually inspect your brake pads and rotors regularly. Look for signs of uneven wear, scoring on the rotors, or excessively thin brake pads. Most vehicles have a small window in the caliper where you can see the pad thickness without removing the wheel.

Brake Pad Replacement: Brake pads should be replaced when they reach their minimum thickness, typically around 3-4mm. Waiting too long can result in damage to the rotors and reduced braking efficiency. Always replace brake pads in pairs (both wheels on the same axle) to ensure even braking performance.

Rotor Maintenance: Rotors may need to be resurfaced or replaced if they become warped or develop significant grooves. Resurfacing can often extend the life of rotors, but there’s a minimum thickness below which they must be replaced entirely.

Brake Fluid Changes: Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This can lead to reduced braking performance and corrosion within the system. Most manufacturers recommend changing brake fluid every 2-3 years.

Caliper Maintenance: Ensure that caliper slide pins are clean and well-lubricated. Stuck slide pins can cause uneven pad wear and reduced braking efficiency. Also, check for any signs of fluid leaks around the caliper pistons.

Addressing Unusual Symptoms: Pay attention to any unusual symptoms such as squealing, grinding noises, vibrations during braking, or a soft brake pedal. These can be indicators of various issues that should be addressed promptly to prevent more serious problems.

Professional Servicing: While some maintenance tasks can be performed by DIY enthusiasts, it’s often best to have your brakes serviced by a professional. They have the tools and expertise to properly diagnose and address any issues with your braking system.

FAQs About Disc Brakes

- How long do disc brakes typically last?

Disc brake pads usually last between 30,000 to 70,000 miles, depending on driving habits and conditions. - Are disc brakes better than drum brakes?

Generally, yes. Disc brakes offer better heat dissipation, more consistent performance, and easier maintenance than drum brakes. - Can I replace disc brake pads myself?

Yes, with proper tools and knowledge, brake pad replacement is a task many DIY enthusiasts can perform. - Why do my disc brakes squeal?

Squealing can be caused by worn brake pads, glazed rotors, or the presence of debris between the pad and rotor. - How often should disc brakes be serviced?

It’s recommended to have your brakes inspected at least once a year or every 12,000 miles, whichever comes first.