Disc brakes have become increasingly popular on bicycles, offering superior stopping power and performance compared to traditional rim brakes. These braking systems work by applying force to a rotor attached to the wheel hub, providing consistent and powerful braking in various conditions. Understanding how disc brakes function can help cyclists appreciate their benefits and maintain them properly for optimal performance.

Disc brakes on bicycles operate using a simple yet effective mechanism. When a rider squeezes the brake lever, it activates a system that causes brake pads to clamp down on a metal disc (rotor) attached to the wheel hub. This friction between the pads and the rotor slows the wheel’s rotation, bringing the bike to a stop. The design allows for more precise control and greater stopping power compared to rim brakes, especially in wet or muddy conditions.

| Component | Function |

|---|---|

| Rotor | Rotating disc attached to wheel hub |

| Caliper | Houses brake pads and pistons |

| Brake pads | Create friction against rotor |

| Brake lever | Activates braking mechanism |

Types of Disc Brakes

There are two main types of disc brakes used on bicycles: mechanical disc brakes and hydraulic disc brakes. Each type has its own advantages and considerations, catering to different rider preferences and bike designs.

Mechanical disc brakes use a cable system similar to traditional rim brakes. When the rider pulls the brake lever, it tensions a cable that runs through the frame or fork to the brake caliper. This cable pull activates a mechanism in the caliper that pushes the brake pads against the rotor. Mechanical disc brakes are generally less expensive and easier to maintain, making them popular on entry-level and mid-range bikes. They offer improved performance over rim brakes but may require more frequent adjustments as the cable stretches and pads wear.

Hydraulic disc brakes, on the other hand, use fluid to transmit force from the brake lever to the caliper. When the rider squeezes the lever, it pushes a piston in the master cylinder, which forces brake fluid through hoses to the caliper. The pressurized fluid then moves pistons in the caliper, pressing the brake pads against the rotor. Hydraulic systems provide more consistent and powerful braking with less effort at the lever. They also self-adjust for pad wear, requiring less frequent maintenance. However, hydraulic disc brakes are more complex and expensive, typically found on higher-end bikes.

Both types of disc brakes offer significant advantages over rim brakes, including:

- Better performance in wet and muddy conditions

- More consistent braking on long descents

- Reduced hand fatigue during extended braking periods

- Improved modulation for better control

- No wear on the wheel rim, potentially extending wheel life

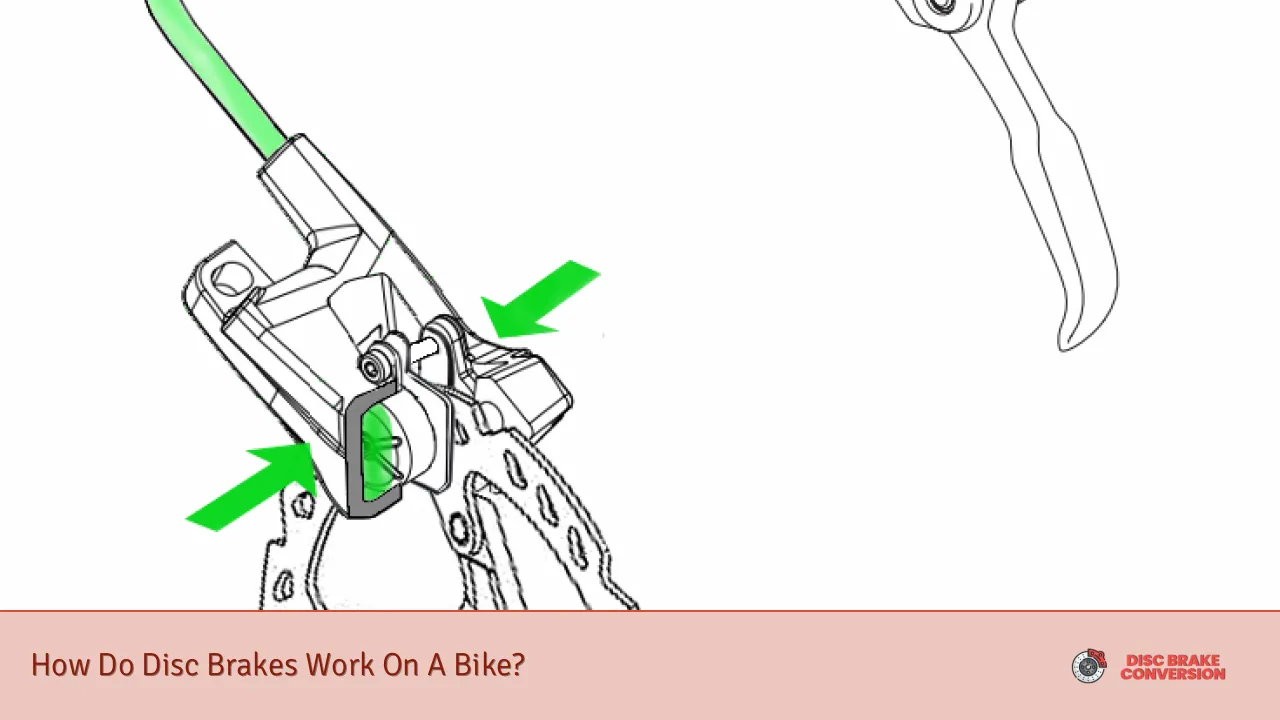

Disc Brake Components

Understanding the key components of a disc brake system is essential for proper maintenance and troubleshooting. Here’s a breakdown of the main parts:

Rotor

The rotor is the metal disc attached to the wheel hub that the brake pads clamp onto. Rotors come in various sizes, typically ranging from 140mm to 203mm in diameter. Larger rotors provide more stopping power and better heat dissipation but add weight. Rotors may have different designs, including solid, vented, or drilled patterns, each offering specific performance characteristics.

Caliper

The caliper is the housing that holds the brake pads and, in hydraulic systems, the pistons. It’s mounted to the frame or fork and positioned so that the pads can grip the rotor when activated. Calipers come in various designs, including single-piston and dual-piston configurations, with higher-end models offering more precise pad movement and better heat management.

Brake Pads

Brake pads are the consumable components that create friction against the rotor to slow the bike. They’re typically made of a semi-metallic or organic compound designed to provide optimal braking performance while minimizing wear on the rotor. Pads need to be replaced periodically as they wear down, with the frequency depending on riding conditions and brake usage.

Brake Lever

The brake lever is the rider’s interface with the braking system. In mechanical disc brakes, the lever pulls a cable, while in hydraulic systems, it actuates a master cylinder. Lever design can significantly affect braking feel and performance, with many high-end levers offering adjustability for reach and bite point.

How Disc Brakes Function

The operation of disc brakes involves a series of steps that translate the rider’s input at the lever into stopping power at the wheel. Here’s a detailed look at how disc brakes work:

1. Lever Activation: When the rider squeezes the brake lever, it initiates the braking process. In mechanical systems, this pulls a cable, while in hydraulic systems, it pushes fluid through the brake line.

2. Force Transmission: The force from the lever is transmitted to the caliper. In mechanical brakes, the cable directly moves an arm in the caliper. In hydraulic systems, the pressurized fluid moves pistons within the caliper.

3. Pad Movement: The movement within the caliper causes the brake pads to move inward towards the rotor. The pads are designed to align perfectly with the rotor’s surface.

4. Friction Generation: As the pads make contact with the spinning rotor, they create friction. This friction converts the kinetic energy of the moving bike into heat energy.

5. Wheel Deceleration: The friction between the pads and rotor slows the rotation of the wheel, thereby decelerating the bike.

6. Heat Dissipation: The heat generated during braking is dissipated through the rotor and caliper. Proper heat management is crucial for maintaining consistent braking performance, especially during long descents.

7. Lever Release: When the rider releases the brake lever, the pads retract slightly from the rotor, allowing the wheel to spin freely again.

This process occurs almost instantaneously, providing riders with responsive and powerful braking on demand. The efficiency of disc brakes in converting rider input to stopping power makes them particularly effective in challenging conditions and high-performance situations.

Maintenance and Care

Proper maintenance is crucial for ensuring the optimal performance and longevity of disc brakes. Here are some key aspects of disc brake care:

- Pad Inspection: Regularly check brake pad thickness and replace pads when they wear down to the manufacturer’s recommended minimum thickness.

- Rotor Care: Keep rotors clean and free from contaminants. Avoid touching the rotor surface with bare hands, as oils can affect braking performance.

- Caliper Alignment: Ensure the caliper is properly aligned with the rotor to prevent rubbing and uneven pad wear.

- Fluid Maintenance: For hydraulic systems, check brake fluid levels and bleed the system as recommended by the manufacturer to remove air bubbles.

- Cable Tension: In mechanical systems, adjust cable tension as needed to maintain optimal lever feel and pad engagement.

- Cleaning: Regularly clean the braking system, especially after riding in muddy or dusty conditions, to prevent buildup that can affect performance.

By following these maintenance practices, riders can ensure their disc brakes continue to provide reliable and powerful stopping performance throughout their cycling adventures.

FAQs About How Do Disc Brakes Work On A Bike

- Are disc brakes more effective than rim brakes?

Yes, disc brakes generally offer better stopping power, especially in wet conditions, and provide more consistent performance on long descents. - How often should I replace my bike’s disc brake pads?

Replacement frequency varies based on usage, but typically every 500-1000 miles or when pad thickness reaches about 1mm. - Can I switch from rim brakes to disc brakes on my existing bike?

It’s usually not possible without replacing the frame, fork, and wheels, as disc brakes require specific mounting points. - Do disc brakes require more maintenance than rim brakes?

While disc brakes may need more frequent pad replacements, they generally require less frequent adjustments and don’t wear down the wheel rim. - Are hydraulic disc brakes better than mechanical ones?

Hydraulic disc brakes offer more power and better modulation but are more expensive and complex to maintain compared to mechanical disc brakes.