Disc brakes are a crucial component of modern vehicle braking systems, providing superior stopping power and performance compared to traditional drum brakes. Understanding how disc brakes function is essential for vehicle owners and enthusiasts alike. This article will explore the inner workings of disc brakes, their components, and how they operate to bring your vehicle to a safe stop.

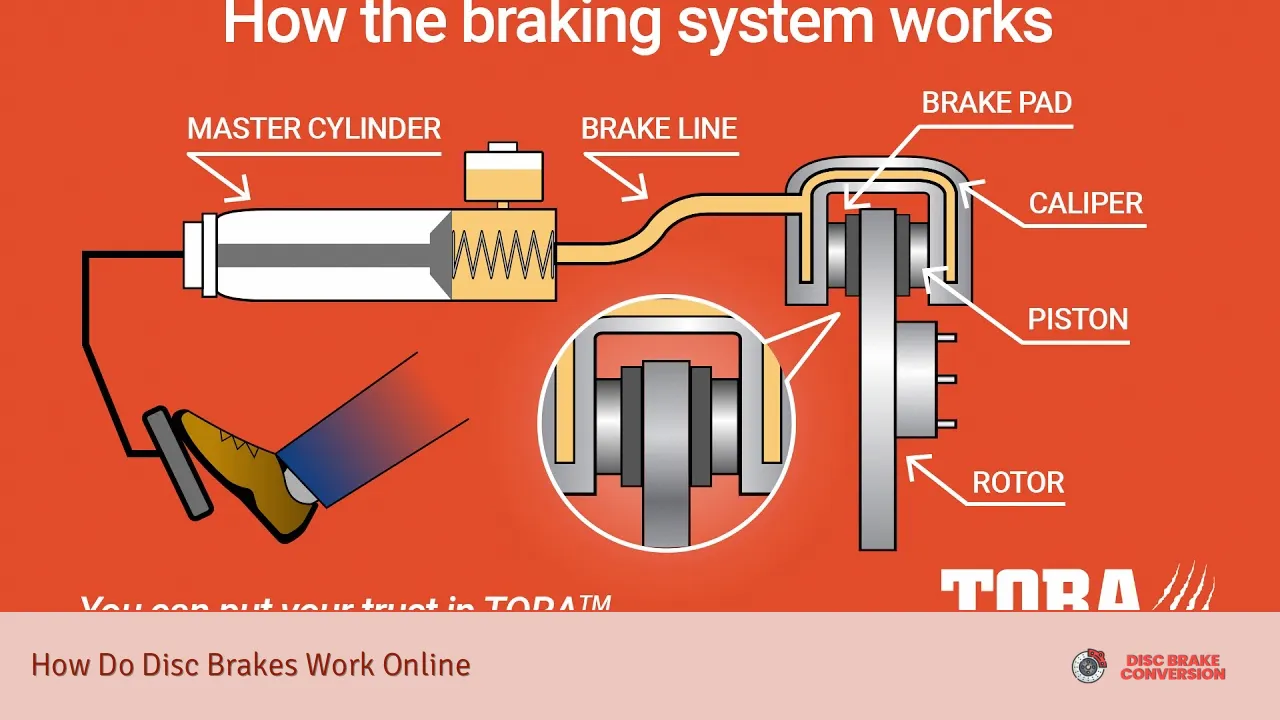

Disc brakes utilize a simple yet effective mechanism to slow down or stop a vehicle. When you press the brake pedal, hydraulic pressure is applied to the brake caliper, which then squeezes the brake pads against a rotating disc (rotor) attached to the wheel. This friction between the pads and the rotor converts the kinetic energy of the moving vehicle into heat, effectively slowing it down.

Let’s take a closer look at the main components of a disc brake system and how they work together:

| Component | Function |

|---|---|

| Brake Rotor | Rotating disc attached to the wheel that provides a friction surface |

| Brake Pads | Friction material that presses against the rotor to create stopping force |

| Caliper | Houses the brake pads and pistons, applies pressure to the pads |

| Brake Lines | Carry hydraulic fluid from the master cylinder to the calipers |

Brake Rotor Design and Function

The brake rotor, also known as the brake disc, is a crucial component of the disc brake system. It’s typically made of cast iron or carbon-ceramic materials and is designed to withstand high temperatures and provide a consistent friction surface. The rotor is directly connected to the wheel hub and rotates with the wheel.

Rotors come in two main designs:

- Solid rotors: A single piece of metal with a smooth surface

- Ventilated rotors: Feature internal vanes to improve heat dissipation

Ventilated rotors are more common in modern vehicles, especially on the front wheels, where most of the braking force is applied. The vented design helps to cool the rotor more efficiently, reducing the risk of brake fade during prolonged or heavy braking.

The surface of the rotor is machined to precise specifications to ensure optimal contact with the brake pads. Over time, rotors may develop grooves or become warped due to heat and wear. Regular inspection and maintenance of the rotors are essential for maintaining braking performance and safety.

Brake Pad Composition and Operation

Brake pads are the unsung heroes of the disc brake system. These relatively small components are responsible for creating the friction necessary to slow down your vehicle. Brake pads are composed of a friction material bonded to a metal backing plate.

The friction material used in brake pads can vary, but common types include:

- Semi-metallic: Contains metal fibers for improved heat dissipation

- Ceramic: Quieter operation and less brake dust

- Organic: Made from natural materials, softer and less durable

When you press the brake pedal, hydraulic pressure forces the brake pads against the rotor. The friction material on the pads grips the rotor, converting the kinetic energy of your moving vehicle into heat energy. This process is what ultimately brings your car to a stop.

It’s important to note that brake pads wear down over time and need regular replacement. Most modern vehicles are equipped with wear indicators that produce a squealing noise when the pads are nearing the end of their service life.

Caliper Mechanics and Hydraulic System

The brake caliper is the component that houses the brake pads and the hydraulic pistons that apply pressure to them. Calipers come in two main types:

- Fixed calipers: Mounted in a fixed position with pistons on both sides

- Floating calipers: Move laterally and typically have pistons on only one side

When you press the brake pedal, it activates the master cylinder, which pressurizes the brake fluid in the system. This hydraulic pressure is transmitted through the brake lines to the calipers. In a floating caliper design, the pressure moves the piston on one side, pushing the inner brake pad against the rotor. The force of this action also pulls the caliper body, bringing the outer pad into contact with the rotor.

Fixed calipers, often found on high-performance vehicles, have pistons on both sides of the rotor. This design provides more even pressure distribution and can offer improved braking performance.

The hydraulic system is critical to the operation of disc brakes. It multiplies the force applied to the brake pedal, allowing you to stop a heavy vehicle with relatively little effort. Regular inspection of brake lines and proper maintenance of brake fluid levels are essential for ensuring consistent braking performance.

Heat Dissipation and Brake Performance

One of the key advantages of disc brakes over drum brakes is their superior ability to dissipate heat. As the brake pads grip the rotor, a significant amount of heat is generated. Efficient heat dissipation is crucial for maintaining consistent braking performance and preventing brake fade.

Disc brakes excel at heat dissipation due to their open design. The rotor is exposed to the air, allowing for better cooling. Ventilated rotors take this a step further by incorporating internal vanes that act like a centrifugal pump, drawing cool air from the center of the rotor and expelling hot air from the edges as the wheel rotates.

High-performance vehicles often use drilled or slotted rotors to further improve heat dissipation and reduce the chance of gas buildup between the pad and rotor surface. These designs can also help to clear water and debris from the braking surface in wet conditions.

Proper heat management is essential for maintaining braking performance, especially during heavy use such as in racing or when towing heavy loads. Overheated brakes can lead to a reduction in friction coefficient, causing the brakes to feel “soft” and reducing their effectiveness.

Maintenance and Troubleshooting

Regular maintenance is crucial for ensuring the longevity and performance of your disc brake system. Here are some key maintenance tasks and troubleshooting tips:

- Regularly inspect brake pads for wear and replace them when necessary

- Check rotors for warping, scoring, or uneven wear

- Flush and replace brake fluid according to the manufacturer’s recommendations

- Inspect brake lines and hoses for leaks or damage

- Listen for unusual noises during braking, such as squealing or grinding

Common disc brake issues and their potential causes include:

- Pulsating brake pedal: Often indicates warped rotors

- Squealing brakes: May signify worn brake pads or the presence of contaminants

- Soft brake pedal: Could indicate air in the brake lines or a hydraulic system leak

- Pulling to one side when braking: May be caused by a stuck caliper or uneven pad wear

Addressing these issues promptly can prevent more serious problems and ensure your vehicle’s braking system remains in top condition.

FAQs About Disc Brakes

- How often should disc brakes be serviced?

Disc brakes should be inspected every 12,000 miles or annually, whichever comes first. - Can I replace disc brake pads myself?

Yes, with proper tools and knowledge, brake pad replacement can be a DIY task for many vehicle owners. - Are ceramic brake pads better than semi-metallic?

Ceramic pads are quieter and produce less dust, but semi-metallic pads often provide better performance in high-temperature situations. - How long do disc brake rotors typically last?

Rotors can last anywhere from 30,000 to 70,000 miles, depending on driving habits and conditions. - What causes disc brakes to squeal?

Squealing can be caused by worn pads, glazed rotors, or the presence of contaminants on the braking surface.

Understanding how disc brakes work online can help you maintain your vehicle’s braking system more effectively and recognize potential issues before they become serious problems. Regular maintenance and prompt attention to any brake-related concerns will ensure your vehicle remains safe and reliable on the road.