Disc brakes are an essential component of modern bicycles, providing superior stopping power and performance in various conditions. Proper adjustment of disc brakes is crucial for optimal functioning and rider safety. This comprehensive guide will walk you through the process of adjusting disc brakes, ensuring your bike’s braking system operates at its best.

Disc brakes consist of several key components, including the rotor, caliper, brake pads, and hydraulic or mechanical actuation system. Understanding these parts and their interactions is fundamental to successful brake adjustment. Whether you’re dealing with rubbing, poor braking performance, or routine maintenance, this guide will help you tackle common disc brake issues.

| Disc Brake Type | Adjustment Method |

|---|---|

| Mechanical | Cable tension and pad positioning |

| Hydraulic | Caliper alignment and fluid management |

Tools and Preparation

Before diving into the adjustment process, it’s essential to gather the necessary tools and prepare your workspace. Here’s what you’ll need:

- Allen keys (typically 4mm and 5mm)

- Torque wrench

- Flathead screwdriver

- Clean rags

- Isopropyl alcohol

- Bike stand (optional but recommended)

Ensure your work area is clean and well-lit. If possible, mount your bike on a stand to allow free wheel rotation during the adjustment process. This setup will make it easier to access the brake components and test your adjustments.

Begin by cleaning the brake rotor with isopropyl alcohol and a clean rag. This step removes any dirt, oil, or debris that could interfere with brake performance or contaminate the brake pads. Avoid touching the rotor surface with bare hands, as oils from your skin can reduce braking efficiency.

Inspect the brake pads for wear. If the pad material is less than 1mm thick, it’s time to replace them before proceeding with adjustments. Check the rotor for any visible damage, such as warping or deep scratches, which may require replacement.

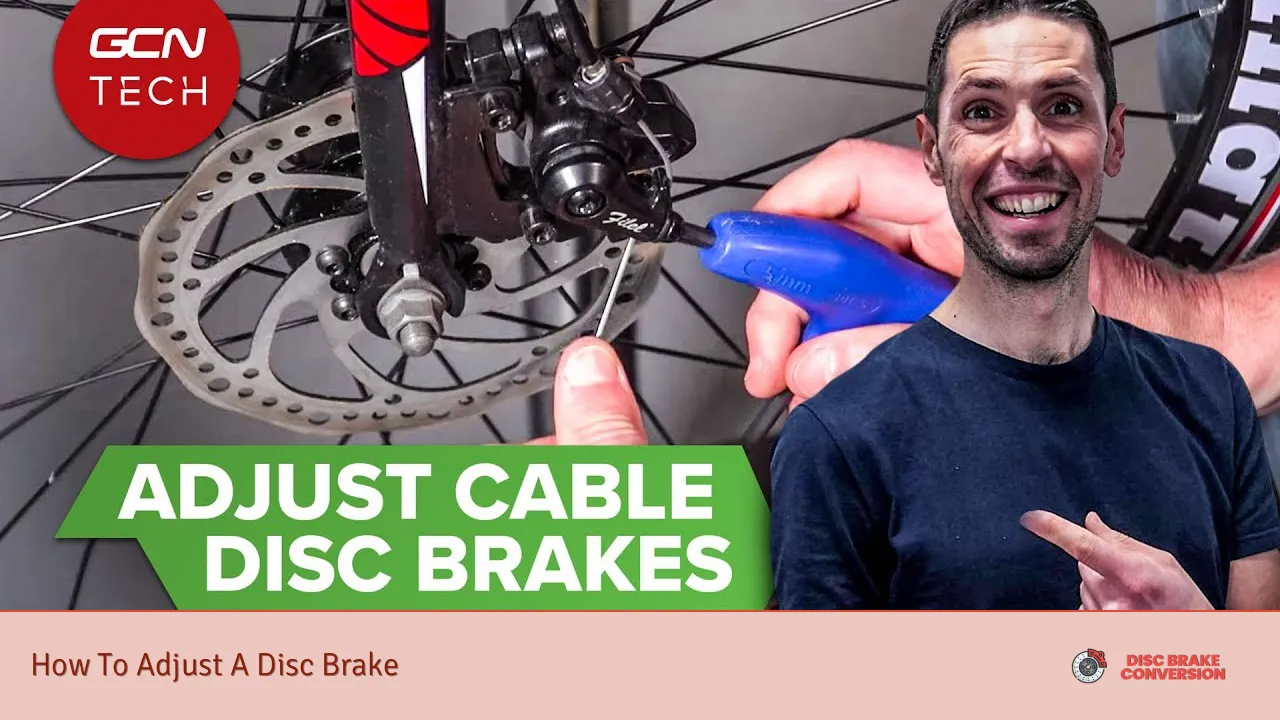

Adjusting Mechanical Disc Brakes

Mechanical disc brakes use a cable system to actuate the brake pads. Follow these steps to adjust them:

1. Loosen the cable anchor bolt: Use an Allen key to slightly loosen the bolt that secures the brake cable to the caliper arm.

2. Adjust pad clearance: Turn the pad adjustment dial or screw to move the stationary pad closer to the rotor. Aim for a gap of about 0.3mm between the pad and rotor.

3. Center the caliper: Loosen the caliper mounting bolts and squeeze the brake lever. This action centers the caliper over the rotor. While holding the lever, retighten the mounting bolts.

4. Set cable tension: Pull the brake cable taut and retighten the cable anchor bolt. Ensure there’s minimal slack in the cable without causing the brake to engage.

5. Fine-tune pad clearance: Adjust the barrel adjuster at the brake lever to fine-tune the cable tension and pad clearance.

6. Test and repeat: Spin the wheel and check for any rubbing. Make small adjustments as needed until the brake operates smoothly without any contact when not engaged.

Remember to tighten all bolts to the manufacturer’s specified torque to ensure safe operation. Over-tightening can damage components, while under-tightening may lead to loosening during rides.

Adjusting Hydraulic Disc Brakes

Hydraulic disc brakes offer more consistent performance and require less frequent adjustment than mechanical systems. However, they may still need occasional tweaking:

1. Check for pad wear: Excessive pad wear can cause the brake lever to pull too close to the handlebar. If this is the case, you may need to bleed the brake system or replace the pads.

2. Align the caliper: Loosen the caliper mounting bolts and squeeze the brake lever firmly. This action centers the caliper over the rotor. While holding the lever, retighten the mounting bolts.

3. Adjust lever reach: Many hydraulic brakes have a small dial or screw near the lever pivot to adjust the lever’s distance from the handlebar. Adjust this to your preference while ensuring the lever doesn’t bottom out against the grip.

4. Reset pistons: If the pads are rubbing, gently push the pistons back into the caliper using a plastic tire lever or a dedicated piston reset tool. Be careful not to damage the pistons or pads.

5. Check for air in the system: If the brake feels spongy or inconsistent, there may be air in the hydraulic lines. In this case, bleeding the brakes is necessary, which is best done by a professional or with a proper brake bleeding kit.

After making adjustments, always test the brakes thoroughly before riding. Spin the wheel and apply the brake, checking for smooth operation and consistent stopping power.

Troubleshooting Common Issues

Even with proper adjustment, disc brakes can sometimes exhibit problems. Here are solutions to common issues:

- Squealing brakes: Clean the rotor and pads with isopropyl alcohol. If the problem persists, the pads may be glazed and require replacement.

- Inconsistent braking: Check for contamination on the rotor or pads. Ensure the rotor is true and not warped. For hydraulic systems, bleeding may be necessary.

- Lever pulls to the bar: This usually indicates worn pads or air in the hydraulic system. Replace pads or bleed the brakes as needed.

- Dragging brake: Realign the caliper and check for stuck pistons. In mechanical systems, ensure the cable isn’t binding.

Regular maintenance and prompt attention to any issues will keep your disc brakes performing optimally. Always prioritize safety and consult a professional if you’re unsure about any aspect of brake adjustment or repair.

FAQs About How To Adjust A Disc Brake

- How often should I adjust my disc brakes?

Adjust them when you notice reduced performance or hear rubbing. Regular bikes may need adjustment every few months. - Can I use household cleaners on my disc brakes?

No, use only isopropyl alcohol or specific brake cleaners to avoid contamination and reduced performance. - Is it normal for new disc brakes to make noise?

Some noise during the break-in period is normal. If it persists after 20-30 rides, adjustment may be needed. - How do I know if my brake pads need replacement?

Replace pads when the friction material is less than 1mm thick or if you see uneven wear patterns. - Can I adjust disc brakes without special tools?

Basic adjustments can be made with Allen keys, but a torque wrench is recommended for proper tightening.