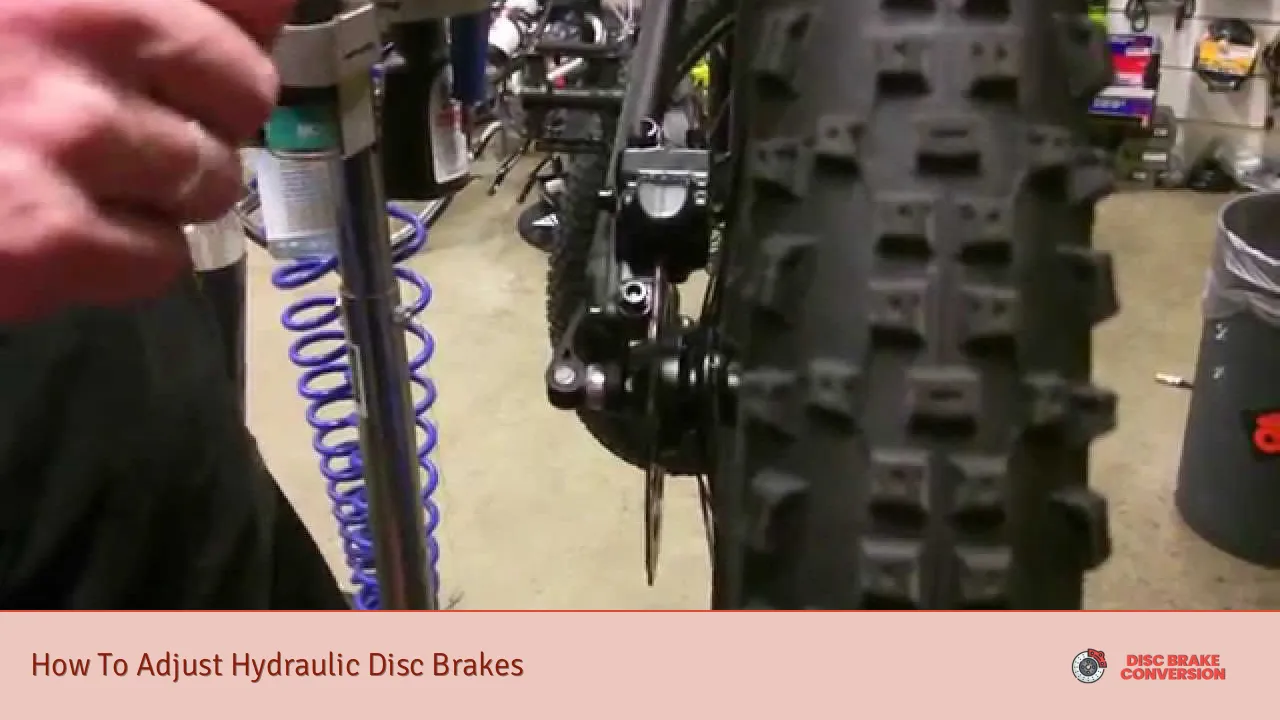

Hydraulic disc brakes are a crucial component of modern bicycles, offering superior stopping power and performance compared to traditional rim brakes. Proper adjustment of these brakes is essential for optimal safety and riding experience. This guide will walk you through the process of adjusting hydraulic disc brakes, ensuring your bike is ready for your next ride.

Hydraulic disc brakes work by using fluid pressure to push brake pads against a rotor attached to the wheel hub. Unlike mechanical disc brakes, which use a cable system, hydraulic brakes offer more consistent performance and require less frequent adjustment. However, they still need occasional fine-tuning to maintain peak performance.

Before we dive into the adjustment process, let’s take a look at the key components of a hydraulic disc brake system:

| Component | Function |

|---|---|

| Brake lever | Initiates braking action |

| Brake line | Transfers hydraulic fluid pressure |

| Caliper | Houses brake pads and pistons |

| Brake pads | Make contact with rotor to slow wheel |

| Rotor | Rotating disc attached to wheel hub |

Preparing for Adjustment

Before you begin adjusting your hydraulic disc brakes, it’s important to gather the necessary tools and prepare your workspace. Here’s what you’ll need:

- 5mm Allen wrench

- Torque wrench

- Clean rags

- Isopropyl alcohol

- Rotor truing tool (optional)

Start by cleaning your brake system thoroughly. Use isopropyl alcohol and a clean rag to wipe down the rotor, caliper, and surrounding areas. This will help you identify any issues and ensure that dirt doesn’t interfere with the adjustment process.

Next, inspect your brake pads for wear. If they’re worn down to less than 1.5mm of pad material, it’s time to replace them. Worn brake pads can significantly impact braking performance and make proper adjustment difficult.

Aligning the Caliper

The first step in adjusting your hydraulic disc brakes is to align the caliper properly. This ensures that the brake pads make even contact with the rotor, maximizing braking power and minimizing noise.

1. Loosen the two bolts that secure the caliper to the frame or fork. Don’t remove them completely; just loosen them enough so that the caliper can move freely.

2. Spin the wheel and apply the brake lever firmly. This will center the caliper over the rotor.

3. While holding the brake lever, tighten the caliper mounting bolts alternately. Use a torque wrench to ensure proper tightening – typically 6-8 Nm, but check your brake manufacturer’s specifications.

4. Release the brake lever and spin the wheel. If you hear any rubbing, repeat the process.

Fine-Tuning Caliper Alignment

If the above method doesn’t completely eliminate rubbing, you may need to fine-tune the alignment:

- Look through the caliper from above. You should see equal space on both sides of the rotor.

- If one side is closer, loosen the mounting bolts slightly and gently push the caliper in the opposite direction.

- Retighten the bolts and check again.

Remember, patience is key when aligning hydraulic disc brakes. Small adjustments can make a big difference in performance.

Adjusting Lever Reach

Lever reach is the distance from the handlebar to the brake lever. Proper adjustment ensures comfortable and effective braking.

1. Locate the reach adjustment screw on your brake lever. It’s usually a small Allen screw near the pivot point.

2. Turn the screw clockwise to move the lever closer to the handlebar, or counterclockwise to move it further away.

3. Adjust until you can comfortably reach the lever with one or two fingers while maintaining a secure grip on the handlebar.

Setting the Bite Point

The bite point is where the brake pads make initial contact with the rotor. Adjusting this can improve brake feel and responsiveness.

1. Find the bite point adjustment screw. On most systems, it’s located on the lever body.

2. Turn the screw clockwise to make the bite point occur earlier in the lever stroke, or counterclockwise for a later bite point.

3. Test the brakes after each adjustment to find your preferred setting.

Note: Not all hydraulic brake systems have a bite point adjustment. Consult your brake manufacturer’s manual for specific instructions.

Bleeding the Brake System

If your brakes feel spongy or lack power after adjustment, you may need to bleed the system to remove air bubbles. This is a more advanced procedure that requires specific tools and brake fluid.

1. Gather brake bleeding kit, appropriate brake fluid, and protective gear.

2. Attach the bleed cup to the caliper bleed port.

3. Open the lever reservoir and add fresh fluid.

4. Pump the lever while opening and closing the bleed port to force air bubbles out.

5. Top up fluid levels and securely close all ports.

Warning: Always use the correct type of brake fluid specified by your brake manufacturer. Mixing fluids can cause system failure.

Maintaining Your Hydraulic Disc Brakes

Regular maintenance will keep your brakes performing at their best:

- Clean rotors regularly with isopropyl alcohol

- Check brake pads for wear and replace when necessary

- Inspect brake lines for damage or leaks

- Keep an eye on fluid levels and top up as needed

By following these adjustment and maintenance procedures, you’ll ensure that your hydraulic disc brakes provide reliable, powerful stopping performance for many rides to come.

FAQs About Hydraulic Disc Brakes

- How often should I adjust my hydraulic disc brakes?

Adjust them when you notice reduced performance or hear rubbing noises. - Can I use any brake fluid for my hydraulic system?

No, always use the specific fluid recommended by your brake manufacturer. - Why are my brakes squealing after adjustment?

This could be due to contaminated rotors or brake pads. Clean them thoroughly. - Is it normal for brake pads to rub slightly?

A very slight rub is acceptable, but persistent rubbing needs adjustment. - How long do hydraulic brake pads typically last?

Depending on riding conditions, they can last anywhere from 500 to 1,200 miles.