Disc brake quiet is a specialized product designed to reduce or eliminate squealing and squeaking noises from disc brakes. This elastomeric multi-polymer compound forms a water-resistant, high-temperature film that absorbs vibrations and dampens noise. Properly applying disc brake quiet can significantly improve your driving experience by eliminating annoying brake sounds and potentially extending the life of your brake components.

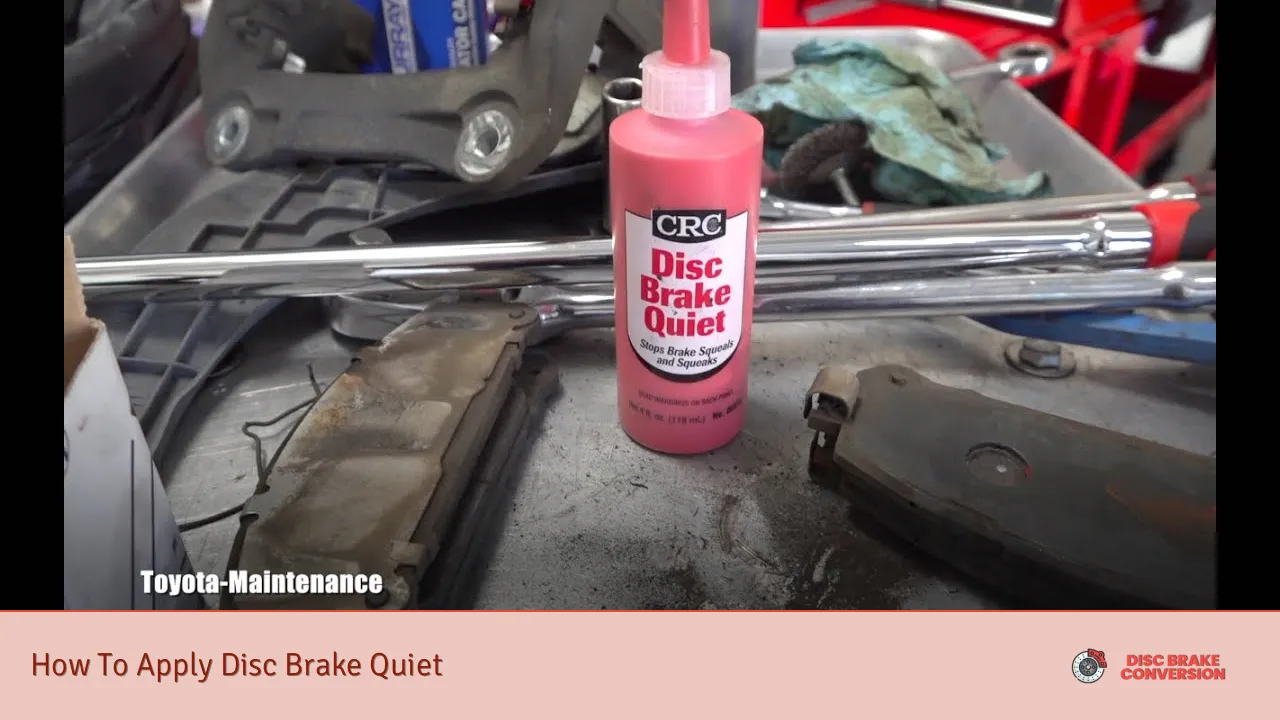

Applying disc brake quiet is a relatively simple process that can be done during routine brake maintenance or as a standalone task to address noise issues. The product comes in various forms, including aerosol sprays, tubes, and squeeze bottles, making it easy to apply in different situations. When used correctly, disc brake quiet can be an effective solution for both DIY enthusiasts and professional mechanics.

| Feature | Benefit |

|---|---|

| Noise reduction | Eliminates squealing and squeaking |

| High-temperature resistance | Withstands brake heat |

| Water-resistant | Protects against moisture |

| Easy application | Suitable for DIY and professionals |

Preparation for Applying Disc Brake Quiet

Before you begin applying disc brake quiet, it’s essential to properly prepare your work area and gather the necessary tools and materials. This preparation will ensure a smooth and effective application process.

First, ensure you have a clean, well-lit workspace. Proper lighting is crucial for accurately applying the product and inspecting your work. If you’re working on a vehicle, make sure it’s securely supported on jack stands if you need to remove the wheels.

Gather the following tools and materials:

- Disc brake quiet product (spray, tube, or squeeze bottle)

- Clean rags or paper towels

- Brake cleaner spray

- Wire brush or sandpaper (fine grit)

- Disposable gloves

- Safety glasses

- Dust mask (if using aerosol products)

Before applying disc brake quiet, it’s crucial to clean the brake components thoroughly. Use brake cleaner spray to remove any dirt, dust, grease, or old brake pad material from the back of the brake pads and the areas where they contact the caliper. A wire brush or fine-grit sandpaper can help remove stubborn debris or rust.

Safety precautions are essential when working with brake components and chemicals. Always wear safety glasses to protect your eyes from debris and splashes. Use disposable gloves to keep your hands clean and protected from harsh chemicals. If you’re using an aerosol disc brake quiet product, consider wearing a dust mask to avoid inhaling any fumes or overspray.

It’s important to note that disc brake quiet should not be applied to brake rotors, the friction surface of brake pads, or any moving parts of the brake system. Doing so can severely impact brake performance and safety. Always read the product instructions carefully before use.

Step-by-Step Application Process

Now that you’ve prepared your workspace and gathered the necessary materials, it’s time to apply the disc brake quiet. Follow these steps carefully to ensure proper application:

1. Remove the brake pads: If the pads are still installed, remove them from the caliper. This will give you better access to the back of the pads where the product needs to be applied.

2. Clean the pads: Use brake cleaner and a clean rag to thoroughly clean the back of the brake pads. Ensure all dirt, grease, and debris are removed.

3. Shake or knead the product: If using an aerosol can, shake it well. For tubes or squeeze bottles, knead the product to ensure it’s well-mixed.

4. Apply to outboard pads: Apply a liberal amount of disc brake quiet to the steel backing plate of each outboard pad. Spread it evenly over the entire surface, but avoid getting any on the friction material of the pad.

5. Apply to inboard pads: For the inboard pads, apply a single strip about the width of the applicator along the steel backing plate.

6. Allow to set: Let the product set for about 10 minutes. It may still be tacky when you install the pads, which is normal.

7. Reinstall the pads: Carefully reinstall the brake pads into the caliper, ensuring they are correctly positioned.

8. Reassemble the brakes: Reattach the caliper and any other components you removed during the process.

9. Repeat for other wheels: If you’re treating all your brakes, repeat the process for each wheel.

10. Test the brakes: Before driving at normal speeds, test your brakes at low speeds in a safe area to ensure proper function.

Remember, disc brake quiet should never be applied to the friction surface of the pads or any part of the rotor. It’s designed only for the back of the pads where they contact the caliper pistons or caliper brackets.

Best Practices and Tips

To get the most out of your disc brake quiet application and ensure long-lasting results, consider these best practices and tips:

- Apply in moderate temperatures: For best results, apply disc brake quiet when the ambient temperature is between 50°F and 90°F (10°C to 32°C). Extreme temperatures can affect the product’s consistency and drying time.

- Use sparingly: While you want to ensure good coverage, avoid over-applying the product. A thin, even layer is usually sufficient. Excess product can squeeze out when the brakes are applied, potentially contaminating the rotor or friction surface of the pads.

- Check compatibility: Some high-performance or racing brake pads come with their own noise reduction shims or treatments. In these cases, additional disc brake quiet may not be necessary or recommended. Always check your brake pad manufacturer’s guidelines.

- Regular inspection: After applying disc brake quiet, periodically inspect your brakes during routine maintenance. If you notice the product has worn off or is no longer effective, reapply as needed.

- Consider professional application: If you’re not comfortable working on your brakes or if the noise persists after application, consider having a professional mechanic apply the product or diagnose any underlying issues.

- Address other brake issues: While disc brake quiet can effectively reduce noise, it’s not a cure-all for brake problems. If you’re experiencing persistent squealing, grinding, or other unusual noises, there may be other issues such as worn pads, warped rotors, or stuck caliper pistons that need addressing.

- Use quality products: Opt for reputable brands of disc brake quiet. CRC, Permatex, and 3M are well-known manufacturers that produce reliable products.

- Store properly: After use, store your disc brake quiet product in a cool, dry place. If using a tube or squeeze bottle, ensure the cap is tightly sealed to prevent the product from drying out.

By following these best practices, you can maximize the effectiveness of disc brake quiet and maintain quieter, smoother-operating brakes for a longer period.

FAQs About How To Apply Disc Brake Quiet

- Can I apply disc brake quiet to motorcycle brakes?

Yes, disc brake quiet can be used on motorcycle brakes, following the same application process as for car brakes. - How long does disc brake quiet typically last?

When properly applied, disc brake quiet can last several months to a year, depending on driving conditions and brake usage. - Will disc brake quiet affect my brake performance?

When applied correctly to only the back of the pads, disc brake quiet should not affect brake performance or stopping power. - Can I use disc brake quiet on drum brakes?

No, disc brake quiet is specifically formulated for disc brake systems and should not be used on drum brakes. - Is it necessary to remove the wheels to apply disc brake quiet?

While not always necessary, removing the wheels provides better access and ensures a more thorough application.