Changing disc brakes is an essential maintenance task that ensures your vehicle’s safety and performance on the road. This process involves replacing worn brake pads and, if necessary, the brake rotors. While it may seem daunting at first, with the right tools and knowledge, you can successfully change your disc brakes and save money on mechanic fees.

Disc brakes are the most common type of braking system in modern vehicles, consisting of brake pads that clamp onto a rotor to slow down or stop the car. Over time, these components wear down and require replacement to maintain optimal braking performance. Regular maintenance of your disc brakes not only ensures your safety but also prevents more costly repairs down the line.

Before we dive into the step-by-step process, let’s take a look at the key components involved in changing disc brakes:

| Component | Function |

|---|---|

| Brake Pads | Provide friction to slow down the rotor |

| Rotor (Disc) | Rotating component that brake pads clamp onto |

| Caliper | Houses the brake pads and pistons |

| Brake Fluid | Hydraulic fluid that transfers force to the brake pads |

Preparation and Safety Measures

Before you begin changing your disc brakes, it’s crucial to prioritize safety and gather all necessary tools and materials. This preparation will ensure a smooth and efficient brake change process.

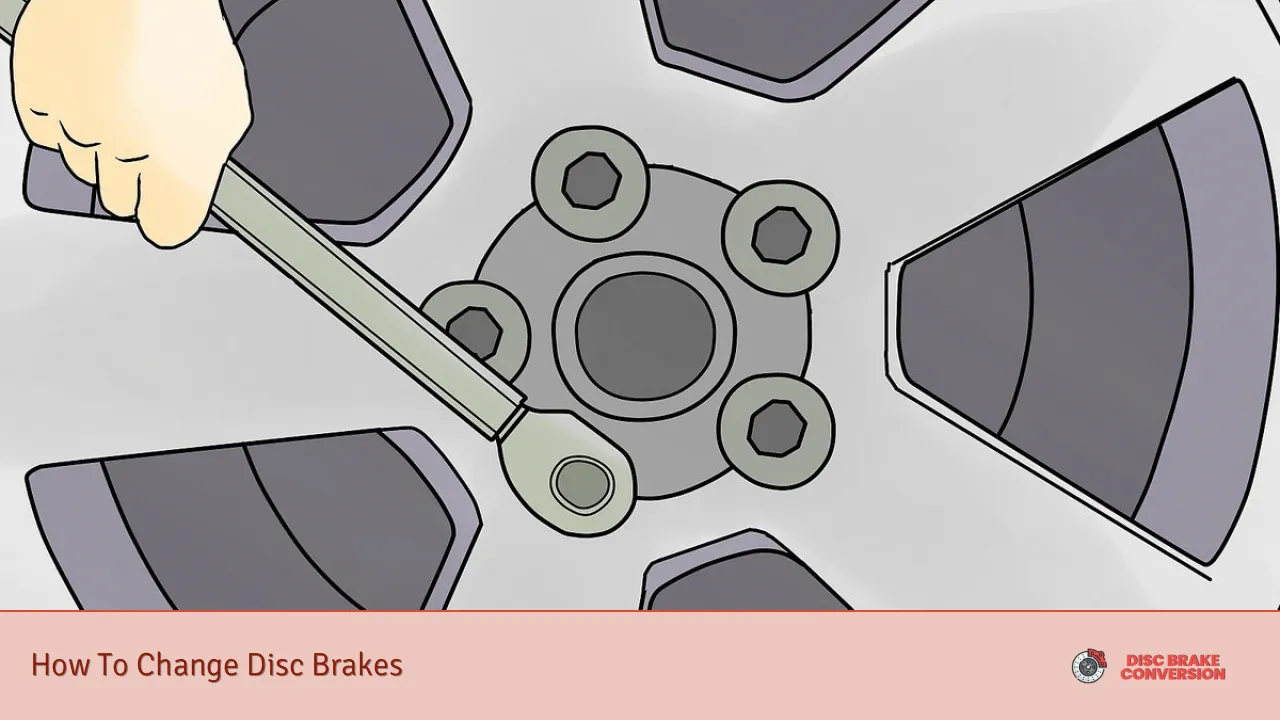

First and foremost, park your vehicle on a flat, level surface and engage the parking brake. This step prevents any unexpected movement while you’re working on the brakes. Next, loosen the lug nuts on the wheel you’ll be working on, but don’t remove them completely yet. This step makes it easier to remove the wheel once the car is jacked up.

Now, it’s time to lift the vehicle. Use a hydraulic jack to raise the car, placing it at the designated jack point for your specific vehicle model. Once the car is lifted, place jack stands under the frame for added safety. Never rely solely on a hydraulic jack to support the weight of your vehicle.

With the car securely lifted, you can now remove the wheel completely. This step gives you full access to the brake assembly.

Before proceeding further, gather all the necessary tools and materials:

- New brake pads

- New rotors (if needed)

- Brake caliper tool

- Socket wrench set

- Torque wrench

- C-clamp or brake caliper piston tool

- Brake cleaner spray

- Anti-seize lubricant

- Disposable gloves

- Safety glasses

It’s important to note that brake dust can be harmful if inhaled, so wear a dust mask and work in a well-ventilated area. Additionally, brake fluid is corrosive, so protect your skin and eyes with gloves and safety glasses.

Removing the Old Brake Components

With your vehicle safely elevated and the wheel removed, you can now begin the process of removing the old brake components. This step is crucial in preparing for the installation of new brake pads and, if necessary, rotors.

Start by locating the brake caliper, which is the large clamp-like component that houses the brake pads. You’ll need to remove this to access the brake pads and rotor. Most calipers are held in place by two bolts on the back. Use your socket wrench to remove these bolts, being careful not to lose them.

Once the bolts are removed, you can lift the caliper off the rotor. Be gentle during this process, as the caliper is still connected to the brake line. Never let the caliper hang by the brake line, as this can cause damage. Instead, use a piece of wire or a bungee cord to suspend the caliper from the wheel well or another secure part of the vehicle.

With the caliper out of the way, you can now remove the old brake pads. They should slide out easily from the caliper bracket. If they’re stuck, use a flathead screwdriver to gently pry them out. Take note of how the pads are positioned, as you’ll need to install the new ones in the same orientation.

Next, inspect the rotor. If it needs to be replaced, you’ll need to remove the caliper bracket by unscrewing the two bolts that hold it to the steering knuckle. Once the bracket is off, the rotor should slide right off the wheel hub. If it’s stuck due to rust or corrosion, you may need to tap it gently with a rubber mallet to loosen it.

Before installing the new components, it’s crucial to clean the area thoroughly. Use your brake cleaner spray to remove any dust, debris, or old brake pad material from the caliper bracket and the area around the wheel hub. This ensures proper fitment and function of your new brake components.

Installing New Brake Pads and Rotors

With the old components removed and the area cleaned, you’re now ready to install the new brake pads and, if necessary, rotors. This process requires attention to detail to ensure proper installation and optimal brake performance.

If you’re replacing the rotors, start by installing the new rotor onto the wheel hub. Make sure it sits flush against the hub surface. If there’s any rust or corrosion preventing this, clean it off with a wire brush. Once the rotor is in place, secure it temporarily with a lug nut to prevent it from falling off while you work on the other components.

Next, focus on the brake pads. Before installing them, you need to retract the caliper piston. This creates space for the new, thicker brake pads. Use a C-clamp or a specialized brake caliper piston tool for this task. Place the tool over the caliper, with one end on the piston and the other on the back of the caliper, and slowly tighten it until the piston is fully retracted.

Now you can install the new brake pads into the caliper bracket. Make sure they’re oriented correctly, matching the position of the old pads you removed earlier. Most brake pads have a wear indicator – a small metal tab – which should be positioned on the inner side of the rotor.

With the new pads in place, it’s time to reinstall the caliper. Carefully position it over the new pads and rotor, making sure not to twist or kink the brake line. Reinsert the caliper bolts and tighten them to the manufacturer’s specified torque. This step is crucial for proper brake function, so use a torque wrench to ensure accuracy.

Before moving on, apply a small amount of anti-seize lubricant to the caliper slider pins. This helps ensure smooth operation of the caliper over time. Be careful not to get any lubricant on the brake pads or rotor surface, as this can severely impact braking performance.

Finally, double-check all your work. Make sure all bolts are properly tightened, the rotor spins freely, and there’s no interference between the rotor and any other components.

Finishing Up and Testing

After successfully installing your new brake components, there are a few final steps to complete the job and ensure everything is working correctly. This phase is crucial for your safety and the proper function of your newly installed brakes.

Start by reinstalling the wheel. Hand-tighten the lug nuts in a star pattern to ensure even pressure. Once the wheel is secure, carefully lower the vehicle back to the ground using the jack. With the full weight of the vehicle on the wheel, use a torque wrench to tighten the lug nuts to the manufacturer’s specified torque, again in a star pattern.

Next, it’s time to check and top off the brake fluid. Open the hood and locate the brake fluid reservoir. The brake fluid level may have risen slightly due to the retraction of the caliper piston, so make sure it’s not overfilled. If it needs topping off, use the type of brake fluid recommended in your vehicle’s manual.

Before taking your vehicle for a test drive, it’s important to “bed in” the new brake pads. This process involves a series of controlled stops to properly seat the pads against the rotor surface. Here’s a general procedure:

- Find a safe, open stretch of road

- Accelerate to about 35 mph

- Apply moderate brake pressure to slow down to about 5 mph

- Repeat this process 5-6 times

- Then, accelerate to about 55 mph

- Brake firmly to about 5 mph

- Repeat this 3-4 times

- Drive for a few minutes without braking to allow the brakes to cool down

This bedding process helps transfer an even layer of brake pad material to the rotor surface, which improves brake performance and reduces the likelihood of brake squeal.

Finally, take your vehicle for a test drive. Pay close attention to how the brakes feel. They should be firm and responsive, without any pulsation or pulling to one side. Listen for any unusual noises like squealing or grinding.

Remember, new brakes may feel different from your old ones. They might be more sensitive or require slightly more pressure. This is normal and you’ll adjust to the feel over time. However, if you experience any significant issues or are unsure about the brake performance, don’t hesitate to have them checked by a professional mechanic.

By following these steps, you’ve successfully changed your disc brakes, saving money and gaining valuable mechanical experience. Regular maintenance like this not only ensures your safety on the road but also extends the life of your vehicle’s braking system.

FAQs About How To Change Disc Brakes

- How often should I change my disc brakes?

Typically, brake pads should be replaced every 50,000 miles, but this can vary based on driving habits and conditions. - Can I change just the brake pads without replacing the rotors?

Yes, but it’s often recommended to replace or at least resurface rotors when changing pads for optimal performance. - How long does it take to change disc brakes?

For a DIY job, expect to spend 2-4 hours per axle, depending on your experience and the specific vehicle. - What tools do I need to change disc brakes?

Essential tools include a jack, jack stands, socket set, torque wrench, and a caliper piston tool. - How do I know if my rotors need to be replaced?

Signs include visible scoring or grooves, significant rusting, or if the rotor thickness is below the manufacturer’s specifications.