Replacing disc brakes is an essential maintenance task for ensuring your vehicle’s safety and optimal performance. This process involves changing both the brake pads and rotors, which work together to provide stopping power. While it may seem daunting at first, with the right tools and knowledge, you can successfully replace your disc brakes and save money on mechanic fees.

Before diving into the replacement process, it’s crucial to understand when your brakes need attention. Signs of worn brakes include squealing or grinding noises, reduced braking performance, and vibrations when applying the brakes. Regular inspections can help you catch wear early and prevent more extensive damage.

| Tools Needed | Parts to Replace |

|---|---|

| Jack and jack stands | Brake pads |

| Lug wrench | Brake rotors |

| C-clamp or caliper piston tool | Hardware kit (if necessary) |

| Socket set and wrenches | Brake fluid (if needed) |

Preparation and Safety Measures

Before you begin the disc brake replacement process, it’s crucial to prioritize safety and proper preparation. Start by parking your vehicle on a flat, level surface and engaging the parking brake. Locate the owner’s manual for specific instructions related to your vehicle model, as brake systems can vary.

Gather all necessary tools and replacement parts before starting. Ensure you have the correct brake pads and rotors for your specific make and model. It’s also wise to wear protective gear such as safety glasses and gloves to shield yourself from brake dust and other potential hazards.

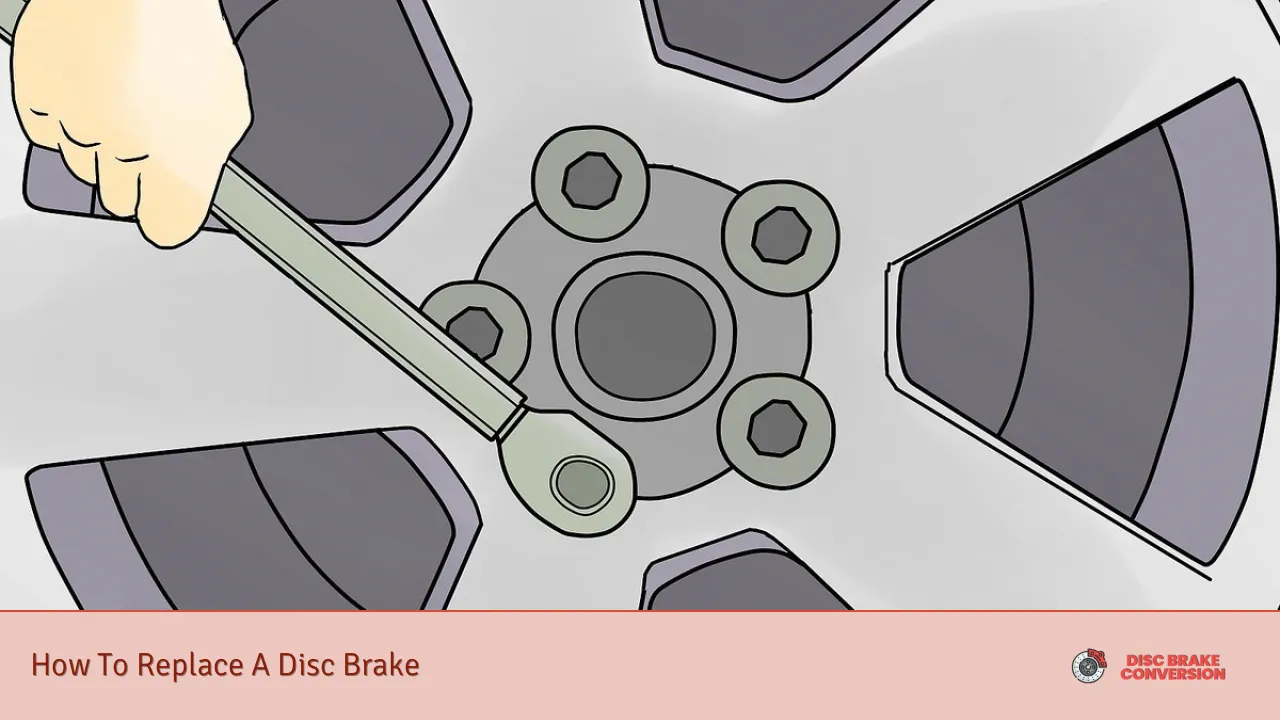

Begin by loosening the lug nuts on the wheel you’ll be working on, but don’t remove them completely yet. Next, use a jack to lift the vehicle and secure it with jack stands. Never rely solely on a jack to support the vehicle’s weight while you work. Once the car is safely elevated, remove the wheel to access the brake assembly.

Removing the Old Brake Components

With the wheel removed, you’ll have a clear view of the brake caliper, pads, and rotor. Start by removing the caliper bolts, typically located on the back of the caliper. Carefully slide the caliper off the rotor and suspend it using a piece of wire or a bungee cord to prevent stress on the brake line.

Next, remove the old brake pads from the caliper bracket. Take note of how they’re positioned, as you’ll need to install the new ones in the same orientation. Inspect the caliper piston and slides for any signs of damage or sticking. If everything looks good, use a C-clamp or caliper piston tool to compress the caliper piston back into its housing. This creates space for the new, thicker brake pads.

To remove the rotor, you may need to take off the caliper bracket by removing its bolts. Some rotors are held in place by a small screw, which you’ll need to remove. If the rotor is stuck due to rust or corrosion, gently tap it with a rubber mallet to loosen it.

Installing New Brake Components

With the old parts removed, it’s time to install the new components. Begin by cleaning the hub surface where the rotor sits using a wire brush or sandpaper to remove any rust or debris. This ensures proper contact between the hub and the new rotor.

Place the new rotor onto the hub, making sure it sits flush. If your vehicle uses a rotor retaining screw, replace it now. Next, reinstall the caliper bracket if you removed it, tightening the bolts to the manufacturer’s specified torque.

Before installing the new brake pads, apply a thin layer of brake lubricant to the back of the pads and any contact points with the caliper bracket. This helps prevent squeaking and ensures smooth operation. Place the new pads into the caliper bracket, making sure they’re oriented correctly.

Reassembling the Brake System

With the new pads in place, carefully position the caliper over the rotor and pads. Reinsert the caliper bolts and tighten them to the specified torque. It’s crucial not to overtighten these bolts, as this can cause the caliper to bind.

Before reinstalling the wheel, check the brake fluid level in the master cylinder reservoir. The level may have risen due to the piston being compressed, so you might need to remove some fluid to prevent overflow when you press the brake pedal.

Reinstall the wheel, hand-tightening the lug nuts. Lower the vehicle back to the ground and use a torque wrench to tighten the lug nuts to the correct specification in a star pattern. This ensures even pressure and prevents warping of the rotor.

Final Steps and Testing

With everything reassembled, it’s time to test your work. Sit in the driver’s seat and slowly pump the brake pedal several times. This action moves the caliper piston back out and brings the pads into contact with the rotor. The pedal may feel soft at first but should become firm after several pumps.

Start the engine and check for any warning lights on the dashboard. If everything looks good, carefully test the brakes at low speeds in a safe area. Listen for any unusual noises and pay attention to how the brake pedal feels. If you notice any issues, double-check your work or consult a professional mechanic.

Remember that new brakes require a break-in period. For the first 300-500 miles, avoid hard stops unless absolutely necessary. This allows the pads and rotors to wear evenly and develop a consistent contact surface, ensuring optimal braking performance.

Maintenance Tips for Longevity

To maximize the lifespan of your new disc brakes, follow these maintenance tips:

- Regularly inspect your brakes for wear and tear

- Keep brake components clean and free from debris

- Avoid “riding” the brakes, which can cause premature wear

- Address any unusual noises or performance issues promptly

- Follow the manufacturer’s recommended maintenance schedule

By replacing your disc brakes yourself and maintaining them properly, you can ensure your vehicle’s safety and save money on professional services. However, if you’re ever unsure about any step in the process, don’t hesitate to consult a qualified mechanic. Your safety on the road is paramount.

FAQs About How To Replace A Disc Brake

- How often should disc brakes be replaced?

Typically, brake pads need replacement every 30,000 to 70,000 miles, while rotors can last 50,000 to 70,000 miles, depending on driving habits and conditions. - Can I replace just the brake pads without changing the rotors?

It’s possible, but not recommended. Rotors wear unevenly and should be replaced or resurfaced when changing pads for optimal performance. - How long does it take to replace disc brakes?

For a DIY enthusiast, replacing disc brakes on one axle typically takes 2-4 hours, depending on experience and vehicle complexity. - What are the signs that I need new disc brakes?

Common signs include squealing or grinding noises, reduced braking performance, vibration when braking, and visible wear on pads or rotors. - Is it necessary to bleed the brakes after replacing disc brakes?

Usually, bleeding isn’t necessary if you don’t open the hydraulic system. However, if the brake pedal feels spongy, bleeding may be required.