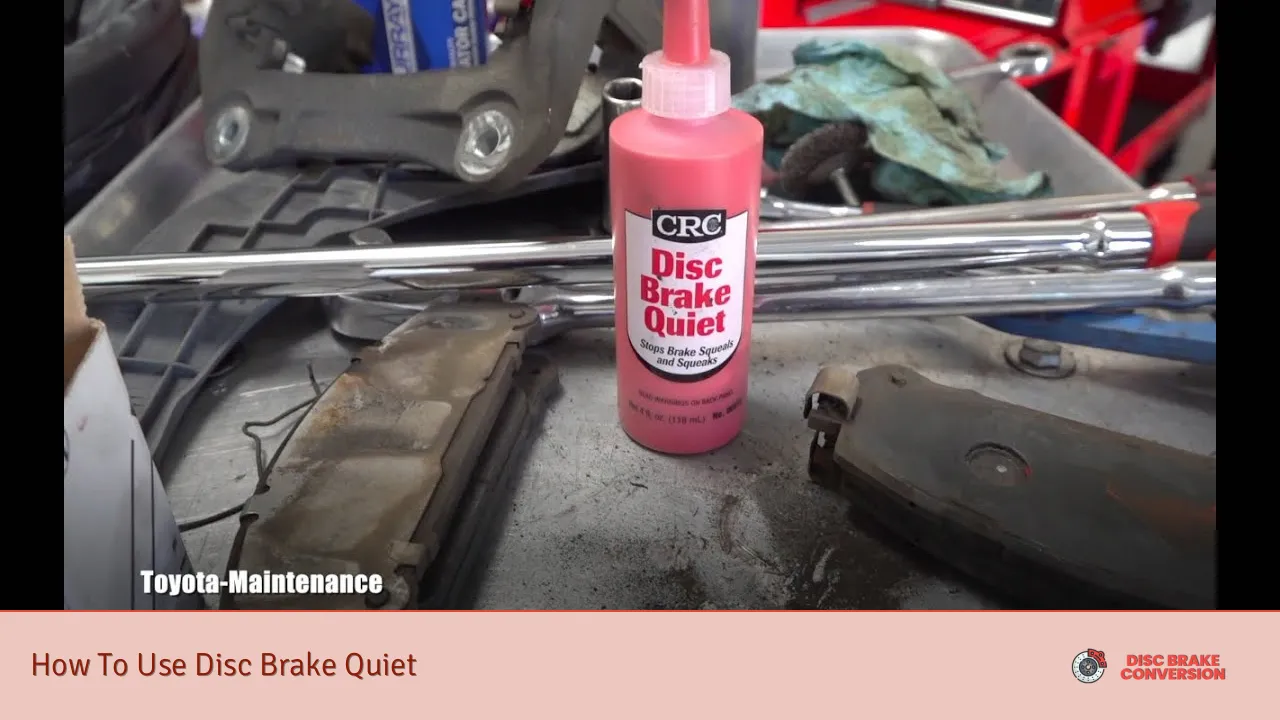

Disc brake quiet is a specialized product designed to reduce or eliminate squealing and squeaking noises from disc brakes. This elastomeric multi-polymer compound forms a water-resistant, high-temperature film that absorbs vibrations and dampens noise. Proper application of disc brake quiet can significantly improve your driving experience by reducing annoying brake sounds and potentially extending the life of your brake components.

Disc brake quiet is commonly used in automotive applications, but it can also be beneficial for other vehicles and machinery with disc brake systems, including motorcycles, bicycles, industrial equipment, and agricultural machinery. The product comes in various forms, including aerosol sprays and gel-like substances, making it versatile and easy to apply.

Before applying disc brake quiet, it’s essential to understand its proper use and application techniques. Incorrect application can lead to reduced brake performance or even brake failure, so following the manufacturer’s instructions and safety precautions is crucial.

| Product Type | Application Method |

|---|---|

| Aerosol Spray | Spray directly on brake pad backing plate |

| Gel/Paste | Apply thin layer with brush or finger |

Preparation and Safety Measures

Before applying disc brake quiet, it’s crucial to prepare your work area and take necessary safety precautions. Proper preparation ensures effective application and helps prevent potential issues.

Start by parking your vehicle on a level surface and engaging the parking brake. If you’re working on rear brakes, chock the front wheels to prevent any movement. Loosen the lug nuts on the wheel you’ll be removing, but don’t take them off completely yet.

Next, jack up the vehicle and secure it with jack stands. Never rely solely on a jack to support your vehicle while working underneath it. Once the vehicle is safely supported, remove the wheel to access the brake assembly.

Put on safety glasses and gloves to protect yourself from debris and chemicals. Work in a well-ventilated area, as some disc brake quiet products may have strong odors or contain volatile compounds. If you’re using an aerosol product, be mindful of overspray and protect surrounding areas if necessary.

Before applying the disc brake quiet, thoroughly clean the brake components. Use brake cleaner to remove any dirt, grease, or old brake pad material from the caliper, rotor, and brake pad backing plates. Allow the cleaned surfaces to dry completely before proceeding.

Inspect the brake components for wear or damage. Look for signs of uneven wear on the brake pads, scoring or warping on the rotors, and any leaks or damage to the calipers. If you notice any issues, address them before applying the disc brake quiet.

Application Process

The application process for disc brake quiet varies slightly depending on whether you’re using an aerosol spray or a gel/paste product. However, the general principles remain the same. Always follow the specific instructions provided by the manufacturer of your chosen product.

For aerosol products:

- Shake the can vigorously for at least one minute to ensure the contents are well-mixed

- Hold the can 6-8 inches away from the brake pad backing plate

- Apply a thin, even coat to the entire surface of the backing plate

- Allow the product to dry for the recommended time (usually 10-15 minutes) before reassembling the brakes

For gel or paste products:

- Use a small brush or your finger to apply a thin layer to the brake pad backing plate

- Ensure complete coverage, but avoid applying too much product

- Allow the product to set according to the manufacturer’s instructions before reassembling

Regardless of the product type, never apply disc brake quiet to the friction surface of the brake pads or the rotor. The product is designed to be used only on the backing plate of the brake pads where they contact the caliper pistons or caliper bracket.

After applying the product, reassemble the brake components carefully. Ensure that all parts are properly seated and that you haven’t inadvertently gotten any disc brake quiet on the rotor or friction surfaces of the pads.

Best Practices and Tips

To get the most out of your disc brake quiet application and maintain optimal brake performance, consider these best practices and tips:

- Apply sparingly: A little goes a long way with disc brake quiet. Excessive application can lead to messy drips and potential contamination of other brake components.

- Reapply as needed: The effectiveness of disc brake quiet can diminish over time. Plan to reapply the product during regular brake maintenance or if you notice the return of brake noise.

- Use on all brake pads: For consistent performance and noise reduction, apply disc brake quiet to all brake pads on the same axle.

- Consider temperature: Some disc brake quiet products perform better in specific temperature ranges. Choose a product appropriate for your climate and driving conditions.

- Complement with other maintenance: While disc brake quiet can reduce noise, it’s not a substitute for proper brake maintenance. Regularly inspect and replace worn brake components as needed.

- Allow proper curing time: Give the product ample time to set before driving the vehicle. This ensures optimal adhesion and performance.

- Keep it clean: Ensure that your brake components are clean and free from debris before applying disc brake quiet. This promotes better adhesion and effectiveness.

Troubleshooting Common Issues

Even with proper application, you may encounter some issues when using disc brake quiet. Here are some common problems and their potential solutions:

Persistent noise: If brake noise continues after applying disc brake quiet, the issue may not be related to pad vibration. Check for other potential causes such as worn rotors, loose caliper hardware, or glazed brake pads.

Reduced braking performance: If you notice a decrease in braking efficiency after application, you may have accidentally contaminated the friction surfaces. Clean the rotors and replace the brake pads if necessary.

Product not adhering: If the disc brake quiet doesn’t seem to be sticking to the backing plate, ensure that the surface is clean and dry before application. Some products may require light scuffing of the backing plate for better adhesion.

Drips or runs: Overapplication can lead to messy drips. Clean up any excess product immediately and use less in future applications.

Allergic reactions: Some individuals may be sensitive to the chemicals in disc brake quiet. If you experience any skin irritation or respiratory issues, discontinue use and consult the product’s safety data sheet.

Remember, while disc brake quiet can be an effective solution for brake noise, it’s not a cure-all for brake problems. If you’re experiencing persistent issues with your brakes, it’s best to consult a professional mechanic for a thorough inspection and diagnosis.

Maintenance and Long-Term Care

To ensure the longevity and effectiveness of your disc brake quiet application, proper maintenance and long-term care are essential. Regular inspection and reapplication when necessary can help maintain quiet brake operation and extend the life of your brake components.

Periodic inspections are crucial. Every time you rotate your tires or perform brake maintenance, check the condition of the disc brake quiet application. Look for signs of wear, peeling, or degradation. If you notice any issues, clean the backing plates and reapply the product.

Be mindful of your driving conditions. If you frequently drive in harsh environments with extreme temperatures, heavy rain, or salty roads, you may need to reapply disc brake quiet more often. These conditions can accelerate the breakdown of the product.

When washing your vehicle, avoid directing high-pressure water streams directly at the brake components. While most disc brake quiet products are water-resistant, prolonged exposure to high-pressure water can potentially wash away the product or force water between the pad and the backing plate.

If you need to replace your brake pads, remember to reapply disc brake quiet to the new pads. This ensures continued noise reduction and optimal brake performance.

Lastly, keep in mind that disc brake quiet is not a permanent solution to all brake noise issues. If you experience persistent or changing brake noises, have your brake system inspected by a qualified mechanic. There may be underlying issues that require attention beyond what disc brake quiet can address.

FAQs About How To Use Disc Brake Quiet

- Can I apply disc brake quiet to the rotor or friction surface of the brake pads?

No, never apply disc brake quiet to the rotor or friction surface of the brake pads. It should only be applied to the backing plate of the pads. - How often should I reapply disc brake quiet?

Reapply disc brake quiet during regular brake maintenance or if you notice the return of brake noise, typically every 12,000 to 15,000 miles. - Will disc brake quiet affect my vehicle’s ABS system?

When applied correctly, disc brake quiet should not affect your ABS system. Always follow the manufacturer’s instructions for proper application. - Can I use disc brake quiet on drum brakes?

Disc brake quiet is specifically designed for disc brake systems. For drum brakes, use products specifically formulated for that brake type. - Is it necessary to remove the brake pads to apply disc brake quiet?

While not always necessary, removing the brake pads allows for easier and more thorough application of the product to the backing plates.