Are you tired of that annoying squeaking sound every time you hit the brakes? Is your vehicle taking longer to come to a stop than it used to? Well, fear not! In this article, we’ll delve into the world of car disc brake machining and how it can be the solution to your braking problems.

So, what exactly is car disc brake machining? Simply put, it’s a process that involves resurfacing the brake discs, also known as rotors, to restore their smoothness and optimal performance. Over time, the constant friction between the brake pads and discs can cause uneven wear and tear, resulting in vibration, noise, and decreased braking efficiency. That’s where disc brake machining comes in.

Picture this: your brake discs are like the smooth surface of a mirror, allowing the brake pads to make even contact and bring your vehicle to a smooth halt. However, with regular use, tiny imperfections and irregularities start to appear on the surface, much like scratches on that once-perfect mirror. These imperfections can lead to ineffective braking, compromising your safety on the road.

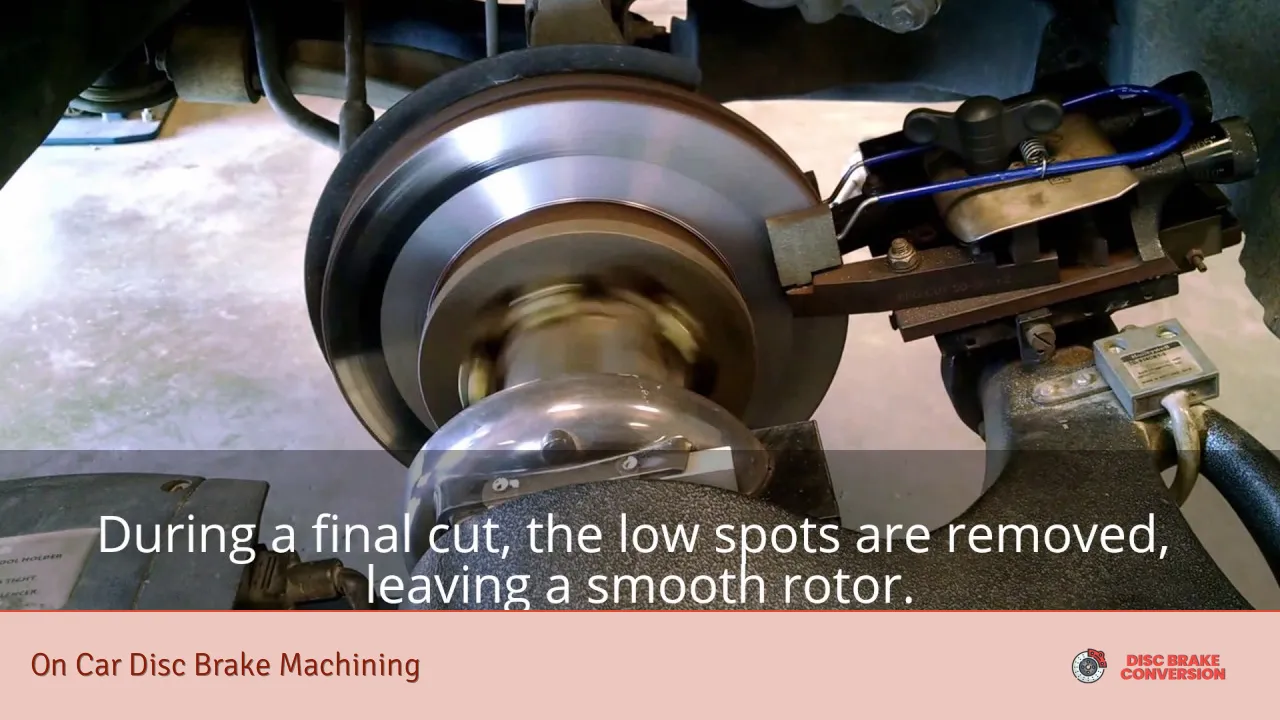

Disc brake machining works like magic to address this issue. Using specialized equipment, a qualified technician carefully removes a thin layer from the surface of the brake discs, eliminating those imperfections. This process not only restores the smoothness but also ensures proper alignment between the discs and brake pads for optimal braking performance.

You might wonder, “Is disc brake machining really necessary?” Well, think of it this way: just like you take care of your body by getting regular check-ups and maintenance, your car deserves the same attention. By investing in disc brake machining, you’re prolonging the life of your brake discs, improving safety, and saving money in the long run. It’s a win-win situation!

If your brakes are giving you trouble, don’t ignore the signs. Car disc brake machining offers a simple yet effective solution to restore your braking system’s performance. Say goodbye to those squeaks and sluggish stops, and embrace the smooth and confident braking experience you deserve. Your safety and peace of mind on the road are worth it!

Revolutionizing the Auto Industry: The Future of Car Disc Brake Machining Unveiled

Are you ready to witness a groundbreaking revolution in the auto industry? Brace yourself as we dive into the future of car disc brake machining. In this cutting-edge article, we’ll explore the latest advancements that are set to transform the way brakes are manufactured and maintained. Get ready to be amazed!

Imagine a world where car disc brake machining is faster, more precise, and supremely efficient. Well, the future is here, and it’s bringing along a host of innovations that will leave you spellbound. Say goodbye to traditional methods as new technologies take center stage.

One of the most remarkable advancements is the integration of artificial intelligence (AI) in brake machining. AI algorithms analyze data from various sensors and systems to optimize the entire process. This means improved accuracy, reduced time, and enhanced overall performance. It’s like having a genius mechanic working tirelessly to ensure your brakes are in top condition.

But that’s not all! The future of car disc brake machining also embraces automation on a whole new level. Robots equipped with advanced vision systems can precisely measure and machine the brake discs with unparalleled accuracy. This eliminates human error and guarantees consistent quality across every vehicle. Just picture a symphony of robotic arms working seamlessly to create flawless brakes.

Furthermore, additive manufacturing, commonly referred to as 3D printing, is set to revolutionize the production of brake components. This technology allows for intricate designs and lightweight structures that enhance performance and fuel efficiency. It’s like sculpting a masterpiece, but this time, the masterpiece ensures your safety on the road.

So, what does all this mean for you, the driver? It means safer vehicles, smoother rides, and increased peace of mind. With the future of car disc brake machining, you can expect improved braking capabilities, shorter stopping distances, and enhanced durability. It’s like having a superhero sidekick, always ready to protect you from potential dangers.

The auto industry is on the verge of a remarkable transformation in car disc brake machining. The integration of AI, automation, and additive manufacturing will redefine the way brakes are made and maintained. Buckle up, because the future is here, and it’s ready to take your driving experience to unprecedented heights.

Say Goodbye to Squeaky Brakes: Breakthrough Innovation in Car Disc Brake Machining

Are you tired of the annoying screeching sound every time you apply the brakes in your car? Well, say goodbye to squeaky brakes because there’s a breakthrough innovation that is revolutionizing car disc brake machining. This cutting-edge technology is set to transform the way brakes are maintained and provide a smoother and quieter driving experience.

Imagine this: you’re cruising down the road, enjoying a peaceful ride when suddenly you need to brake. Instead of hearing that dreadful high-pitched noise, your brakes work silently and efficiently, ensuring a safe stop every time. Thanks to the latest advancements in car disc brake machining, this dream scenario is becoming a reality.

So, what exactly is this breakthrough innovation? It involves state-of-the-art machining techniques that improve the surface of the brake discs, resulting in better performance and reduced noise. By employing advanced precision tools, engineers have developed a process that smooths out imperfections on the disc, eliminating vibrations and minimizing brake noise.

This innovative approach not only enhances braking performance but also extends the lifespan of the brake components. The improved machining technique ensures a perfect fit between the brake pads and discs, reducing wear and tear. As a result, you’ll enjoy longer-lasting brakes, saving you both time and money on frequent replacements.

But how does this breakthrough technology benefit you as a car owner? Firstly, it enhances your driving experience by providing a quiet and comfortable ride. No more cringing every time you step on the brakes. Secondly, it prioritizes safety by improving braking efficiency and responsiveness, giving you peace of mind on the road. And lastly, it offers cost savings by reducing maintenance and replacement costs over time.

The breakthrough innovation in car disc brake machining is transforming the way brakes perform. With its ability to eliminate squeaks and enhance overall braking performance, this advancement is a game-changer for car owners. Say goodbye to annoying brake noises and hello to a smoother, quieter, and safer driving experience. Embrace this cutting-edge technology and enjoy the benefits it brings to your journey.

Saving Time and Money: How Car Disc Brake Machining is Transforming Vehicle Maintenance

Are you tired of spending excessive time and money on car maintenance? Well, here’s some exciting news for you! Car disc brake machining is revolutionizing the way vehicles are maintained, allowing you to save both time and money. In this article, we will explore the incredible benefits of this innovative process.

When it comes to vehicle maintenance, one of the most common and costly issues is brake wear. Over time, brakes can become worn and damaged, leading to decreased performance and potential safety hazards. Traditionally, replacing these worn-out brake discs has been the norm, resulting in significant expenses for car owners. However, with the advent of car disc brake machining, a more efficient and cost-effective solution has emerged.

So, what exactly is car disc brake machining? Essentially, it is a process that involves resurfacing the existing brake discs instead of replacing them entirely. By utilizing specialized machinery, mechanics are able to remove a thin layer of the worn surface, restoring the brake discs to their optimal condition. This not only extends the lifespan of the brakes but also improves their performance, providing you with a smooth and reliable driving experience.

One of the remarkable advantages of car disc brake machining is the substantial cost savings it offers. Rather than purchasing brand new brake discs, which can be quite expensive, you can opt for machining, which typically costs significantly less. This means that you can keep your vehicle running safely without breaking the bank.

Additionally, car disc brake machining saves you precious time. Unlike the process of replacing brake discs, which can take hours or even days, machining can be completed relatively quickly. Mechanics can swiftly resurface the brake discs, allowing you to get back on the road sooner and minimizing disruption to your daily routine.

Car disc brake machining is a game-changer when it comes to vehicle maintenance. It provides a cost-effective alternative to replacing brake discs and saves you valuable time. With this innovative process, you can ensure optimal brake performance and enjoy a smoother driving experience without emptying your wallet. So why wait? Embrace the benefits of car disc brake machining and transform the way you maintain your vehicle today!

Precision and Performance: Exploring the Science Behind Car Disc Brake Machining

Have you ever wondered how your car comes to a smooth, precise stop when you press the brake pedal? The answer lies in the science behind car disc brake machining. In this article, we will delve into the intricacies of this process, uncovering the secrets that ensure both precision and performance.

When it comes to braking systems, disc brakes have become the go-to choice for modern vehicles. Unlike their counterparts, drum brakes, disc brakes offer superior stopping power and heat dissipation. At the heart of this system are the brake rotors, or discs, which undergo a meticulous machining process to achieve optimal functionality.

Disc brake machining involves several key steps, each contributing to the overall performance of the braking system. The first step is the inspection of the rotor’s thickness and condition. This helps identify any potential issues like warping, cracking, or excessive wear. By addressing these problems early on, mechanics can restore the rotors to their original specs.

Next comes the resurfacing or “turning” of the rotors. This process aims to remove a thin layer of material from the rotor’s surface, eliminating any irregularities and creating a smooth, flat contact area for the brake pads. Precision is crucial here, as even slight variations can result in poor braking performance or unwanted vibrations.

To achieve this precision, specialized machinery is employed. The rotor is clamped onto a lathe, which spins it at high speeds while a cutting tool shaves off the imperfections. The result is a perfectly machined rotor, ready to deliver consistent braking power.

Furthermore, disc brake machining plays a vital role in ensuring proper pad-to-rotor contact. By achieving a uniform surface, the brake pads can grip the rotor evenly, maximizing friction and enhancing braking efficiency. This is especially important during emergency stops or demanding driving conditions where split-second reactions can make all the difference.

The science behind car disc brake machining is a testament to the pursuit of precision and performance. Through meticulous inspection, resurfacing, and achieving optimal contact, this process guarantees that your vehicle stops reliably and efficiently. So, the next time you step on the brake pedal, remember the intricate science working behind the scenes to bring you to a safe halt.