Are you tired of dealing with that annoying squeaking sound every time you hit the brakes? Well, you might be facing a common issue known as a warped disc brake. Picture this: you’re driving down the road, enjoying the breeze, and suddenly you need to stop. You press the brake pedal, expecting a smooth halt, but instead, you’re greeted by an unsettling vibration accompanied by that dreadful noise. What’s going on?

A warped disc brake occurs when the brake rotor, the shiny metal disc attached to your wheel, becomes uneven or distorted. It can happen due to various reasons, such as excessive heat, prolonged heavy braking, or even sudden temperature changes. When these factors come into play, the surface of the rotor loses its flatness and becomes warped.

Now, let’s talk about the consequences. When you have a warped disc brake, it affects your vehicle’s braking performance. The uneven surface prevents the brake pads from making proper contact with the rotor, resulting in reduced stopping power. This not only compromises your safety but also increases the braking distance, increasing the risk of accidents.

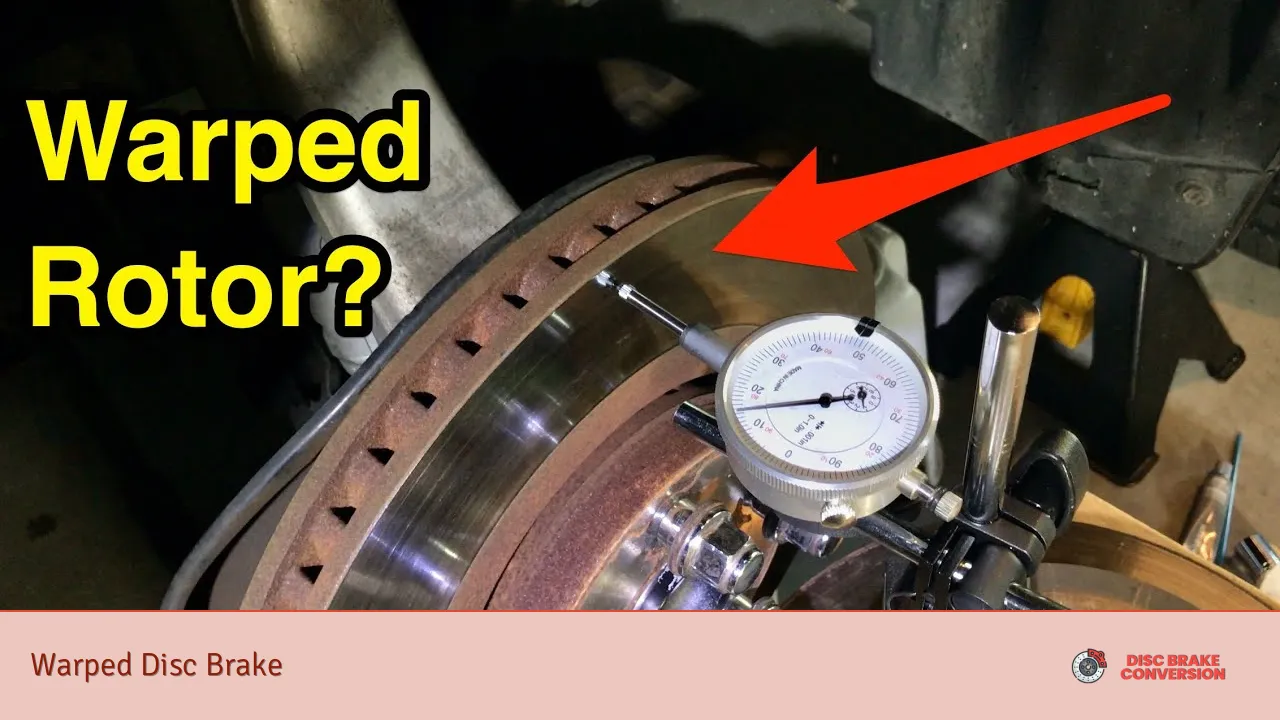

So, how can you diagnose a warped disc brake? One way is through a visual inspection. Check for any signs of irregularities, such as rough patches, grooves, or visible warping on the rotor surface. Another indication is the pulsating sensation you feel through the brake pedal while applying pressure. If you experience any of these symptoms, it’s time to take action.

To fix a warped disc brake, the most common solution is a brake rotor resurfacing or replacement. Resurfacing involves removing a thin layer of the rotor’s surface to restore its flatness. However, in severe cases, where the rotor thickness is below the minimum limit or the warping is too significant, replacing the rotor altogether might be necessary.

Breaking the Mold: Revolutionary Technology Unveiled to Fix Warped Disc Brakes

Are you tired of dealing with warped disc brakes on your vehicle? Well, it’s time to rejoice because revolutionary technology is here to break the mold and fix this annoying issue once and for all. Say goodbye to those pulsating brake pedals and annoying vibrations. In this article, we’ll delve into the details of this groundbreaking innovation that promises to revolutionize the way we experience smooth and reliable braking.

Imagine a world where warped disc brakes are a thing of the past. No more expensive repairs or frequent replacements. This new technology tackles the root cause of warped discs by introducing a cutting-edge material composition that enhances durability and heat dissipation. The days of worrying about brake performance and safety are over.

So, how does this revolutionary technology work? By incorporating advanced composite materials into the manufacturing process, these new disc brakes offer exceptional strength and thermal stability. They can withstand extreme temperatures and intense friction without warping, ensuring consistent contact between the brake pads and rotors.

Beyond their robust construction, these innovative disc brakes also boast improved cooling mechanisms. The design integrates specially engineered cooling vanes that optimize airflow, effectively dissipating heat and preventing excessive temperature buildup. This feature not only reduces the risk of warping but also enhances overall brake performance.

Moreover, this technology doesn’t compromise on efficiency. These upgraded disc brakes maintain excellent stopping power, providing you with a responsive braking experience when you need it most. Whether you’re navigating sharp turns or coming to a sudden stop, you can have peace of mind knowing that your brakes will perform flawlessly.

The unveiling of this revolutionary technology marks a significant breakthrough in the automotive industry. With its superior durability, enhanced cooling, and exceptional performance, these disc brakes are set to transform the way we approach braking systems. Say goodbye to warped discs and hello to a smooth and reliable ride. It’s time to embrace this innovation and experience the future of braking technology.

Road Safety Redefined: Experts Explore Causes and Solutions for Warped Disc Brakes

Introduction:

Have you ever experienced that heart-stopping moment when you step on the brakes, only to feel your car jerking and vibrating? Chances are, you’ve encountered the dreaded problem of warped disc brakes. In this article, we delve into the causes behind this issue and explore effective solutions proposed by experts. By understanding what leads to warped disc brakes and how to address them, we can ensure safer journeys on the road.

Causes of Warped Disc Brakes:

Warped disc brakes are primarily caused by excessive heat buildup during braking. This can occur due to various factors, such as aggressive or prolonged braking, driving downhill for extended periods, or using low-quality brake components. Heat causes the metal rotors to expand unevenly, resulting in warping. Additionally, sudden temperature changes, like driving through puddles after braking, can contribute to this problem.

Solutions to Address Warped Disc Brakes:

-

Quality Brake Components:

Investing in high-quality brake components is crucial to prevent warped disc brakes. Choose reputable brands known for their reliability and durability. These components are designed to dissipate heat efficiently and withstand the demands of heavy braking, reducing the risk of warping. -

Proper Braking Technique:

Practicing proper braking technique can significantly help mitigate the chances of disc brake warping. Instead of applying constant pressure on the brakes for extended periods, opt for a pulsating braking method. This involves applying intermittent pressure to the brake pedal, allowing the brakes to cool down periodically and minimizing heat buildup. -

Regular Maintenance:

Regular maintenance of your braking system is vital for preventing warped disc brakes. Ensure that your brake pads and rotors are inspected and replaced as needed. Over time, brake pads wear down, and worn-out pads can cause excessive heat generation, leading to warping. Regular inspections help identify and rectify issues before they escalate. -

Cooling Systems:

Some experts propose the use of cooling systems for disc brakes, especially in high-performance vehicles. These systems involve the addition of extra cooling fins or ventilation to the brake rotors. Enhanced cooling mechanisms aid in dissipating heat more effectively, reducing the risk of warping.

Conclusion:

Warped disc brakes are a serious concern when it comes to road safety. By understanding the causes behind this issue and implementing effective solutions, we can redefine road safety standards. Investing in quality brake components, practicing proper braking techniques, conducting regular maintenance, and considering cooling systems can go a long way in preventing warped disc brakes. Let’s prioritize road safety and ensure smooth and secure journeys for all.

Unraveling the Mystery: Investigating the Hidden Culprits Behind Warped Disc Brake Epidemic

Have you ever experienced that heart-stopping moment when you step on the brakes, only to feel a pulsation or vibration? It’s a common scenario for many drivers, and the culprit behind this phenomenon may lie in the hidden world of warped disc brakes. In this article, we will delve into the depths of this brake-related mystery, exploring its causes and potential solutions.

Disc brakes are an integral part of a vehicle’s braking system, providing reliable stopping power. However, over time, they can become warped, causing uneven contact between the brake pads and the rotor. This leads to the dreaded pulsation or vibration felt through the brake pedal. But what causes this warping?

One significant factor is heat. During prolonged or aggressive braking, excessive heat builds up in the brake components, causing the metal to expand and contract rapidly. This thermal stress can result in the deformation of the brake rotor, leading to warping. Additionally, environmental factors such as water or road salt can accelerate corrosion on the rotor surface, further exacerbating the issue.

Another hidden culprit is improper installation or maintenance. If the brake rotor is not properly aligned or torqued during installation, it can lead to uneven wear and warping over time. Similarly, neglecting routine maintenance tasks like changing worn-out brake pads or allowing brake fluid contamination can contribute to disc brake problems.

To tackle this issue, preventive measures are key. Regular maintenance checks are essential to ensure the longevity of your brake system. Keep an eye out for signs of wear, such as squealing noises or reduced braking performance. Promptly addressing these issues can prevent further damage and potentially save you from costly repairs down the road.

Understanding the hidden culprits behind the warped disc brake epidemic is crucial for maintaining optimal braking performance and ensuring your safety on the road. Heat, environmental factors, and improper installation or maintenance all play a role in this brake-related mystery. By staying vigilant and addressing any signs of trouble early on, you can keep your brakes functioning smoothly, providing the confidence and peace of mind you deserve while driving.

Revving Up for Change: Auto Industry Pioneers Collaborate on Innovations to Eliminate Warped Disc Brakes

Are you tired of those annoying warped disc brakes that cause your car to vibrate and compromise your safety on the road? Well, you’re not alone. Thankfully, the auto industry pioneers have heard our cries and are collaborating to bring about innovative solutions to eliminate this common problem once and for all.

Warped disc brakes are a thorn in the side of many drivers. They occur when excessive heat builds up during heavy braking, causing the brake rotors to deform and create an uneven surface. This leads to vibrations, reduced braking performance, and ultimately poses a risk to both driver and passengers. But worry not, as the auto industry pioneers are determined to address this issue head-on.

Through collaboration and cutting-edge research, these visionary minds are devising groundbreaking technologies to combat warped disc brakes. One such innovation involves the use of advanced materials that can withstand extreme heat and maintain their structural integrity. By integrating these materials into the manufacturing process, the pioneers aim to create more durable and heat-resistant brake discs that will resist warping even under intense braking conditions.

But that’s not all. These industry leaders are also exploring new cooling mechanisms to dissipate heat effectively. By improving the ventilation and cooling systems around the brake discs, they intend to keep temperatures in check, reducing the likelihood of warping. Imagine cruising down the highway with confidence, knowing that your brakes are operating flawlessly, thanks to these ingenious advancements.

Furthermore, the collaboration extends beyond material enhancements and cooling mechanisms. The auto industry pioneers are working closely with experts in data analytics and machine learning to develop intelligent braking systems. These systems will continuously monitor various parameters, such as temperature, pressure, and driving conditions, to optimize brake performance and prevent potential issues like disc warping. It’s like having a co-pilot dedicated to keeping your brakes in top shape and ensuring your safety on the road.