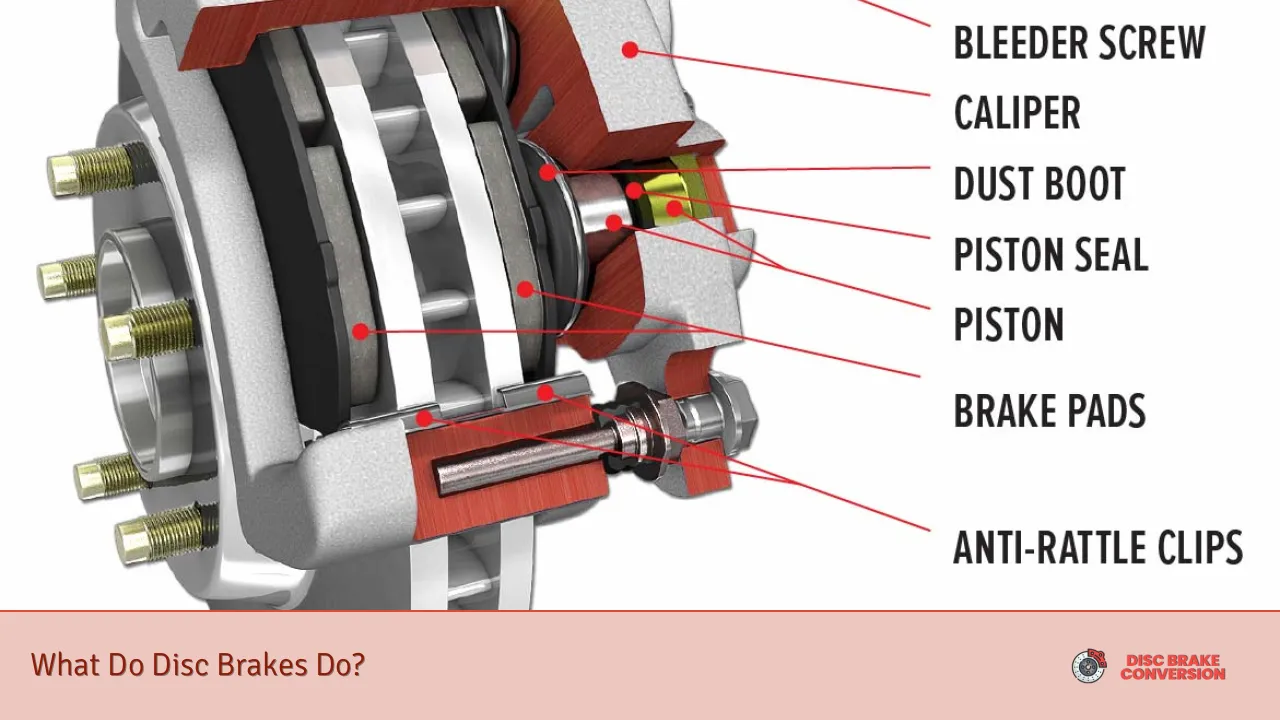

Disc brakes are a crucial component of modern vehicle braking systems, designed to slow down or stop a vehicle by converting kinetic energy into heat through friction. These brakes consist of a flat, circular disc (rotor) attached to the wheel hub and a caliper that houses brake pads. When the driver applies pressure to the brake pedal, the caliper squeezes the brake pads against the rotor, creating friction that slows the wheel’s rotation and, consequently, the vehicle.

The primary function of disc brakes is to provide efficient, reliable, and consistent stopping power across various driving conditions. They offer superior performance compared to older drum brake systems, particularly in terms of heat dissipation, which is crucial for maintaining braking effectiveness during prolonged or repeated use. Disc brakes are now standard on most modern vehicles, from passenger cars to heavy-duty trucks and high-performance sports cars.

| Component | Function |

|---|---|

| Rotor | Rotating disc attached to wheel hub |

| Caliper | Houses brake pads and applies pressure |

| Brake Pads | Creates friction against rotor |

| Hydraulic System | Transfers force from pedal to caliper |

How Disc Brakes Operate

The operation of disc brakes involves a precise interaction between several key components. When a driver presses the brake pedal, it initiates a chain reaction within the braking system. The pedal’s movement activates a master cylinder, which pressurizes brake fluid in the hydraulic lines. This pressurized fluid is then transmitted to the brake calipers at each wheel.

As the hydraulic pressure increases, it forces pistons within the caliper to move. These pistons push the brake pads against the spinning rotor, which is attached to the wheel. The friction generated between the pads and the rotor creates the braking force that slows down the vehicle. The amount of pressure applied to the brake pedal directly correlates to the clamping force of the caliper, allowing for precise control over the vehicle’s deceleration.

One of the key advantages of disc brakes is their self-adjusting nature. As the brake pads wear down over time, the caliper pistons automatically extend further to maintain proper contact with the rotor. This self-adjustment ensures consistent braking performance throughout the life of the brake pads, unlike drum brakes which may require manual adjustments.

The design of disc brakes also allows for excellent heat dissipation. During braking, a significant amount of kinetic energy is converted into heat. The open design of the rotor, often featuring ventilation channels, allows air to flow through and around it, quickly cooling the system. This efficient cooling prevents brake fade, a condition where brakes lose effectiveness due to overheating, which is particularly important during prolonged or repeated braking scenarios.

Types of Disc Brake Systems

There are two main types of disc brake systems commonly used in vehicles:

- Fixed Caliper: In this design, the caliper is mounted rigidly to the vehicle and contains pistons on both sides of the rotor. When activated, these pistons push the brake pads from both sides simultaneously.

- Floating Caliper: This more common design features a caliper that can move laterally. It typically has one or more pistons on the inboard side. When activated, the piston(s) push the inner pad against the rotor, while the caliper itself slides to bring the outer pad into contact.

Both systems have their merits, with fixed calipers often found in high-performance applications due to their rigidity and even pressure distribution, while floating calipers are more common in everyday vehicles due to their simpler design and cost-effectiveness.

Advantages of Disc Brakes

Disc brakes offer several significant advantages over traditional drum brakes, making them the preferred choice for most modern vehicles. These benefits contribute to enhanced safety, performance, and reliability in various driving conditions.

Superior Stopping Power: Disc brakes provide more consistent and powerful braking force compared to drum brakes. The direct contact between the brake pads and the rotor allows for more efficient energy transfer, resulting in shorter stopping distances. This improved performance is particularly noticeable in emergency braking situations, where every foot of stopping distance can be critical.

Better Heat Dissipation: One of the most significant advantages of disc brakes is their ability to dissipate heat quickly. The open design of the rotor allows air to flow freely around it, cooling the brake components more effectively than enclosed drum brakes. This enhanced cooling capacity helps prevent brake fade, a condition where brakes lose effectiveness due to overheating during prolonged or repeated use.

Improved Wet Weather Performance: Disc brakes perform better in wet conditions compared to drum brakes. Water can easily escape from the surface of the disc, whereas it tends to collect inside drum brakes, reducing their effectiveness. The self-cleaning action of disc brakes, where centrifugal force throws water and debris off the rotor, ensures more consistent performance in various weather conditions.

Easier Maintenance and Inspection: Disc brake systems are generally easier to inspect and maintain than drum brakes. Brake pad wear can be checked without removing the wheel in many cases, and pad replacement is typically a simpler process. This ease of maintenance encourages more regular inspections and timely replacements, contributing to overall vehicle safety.

Self-Adjusting Mechanism: Unlike drum brakes that may require manual adjustments as components wear, disc brakes are self-adjusting. The caliper pistons automatically compensate for brake pad wear, ensuring consistent contact with the rotor and maintaining braking performance over time.

Reduced Brake Fade: The superior heat dissipation of disc brakes significantly reduces the likelihood of brake fade during heavy use. This is particularly important for vehicles that frequently encounter challenging driving conditions, such as mountain descents or high-speed driving.

Linear Braking Response: Disc brakes provide a more linear and predictable braking response compared to drum brakes. This characteristic allows drivers to modulate braking force more precisely, enhancing overall vehicle control and safety.

Maintenance and Care of Disc Brakes

Proper maintenance of disc brakes is essential for ensuring optimal performance, safety, and longevity of the braking system. Regular care not only enhances the vehicle’s stopping power but also prevents costly repairs and potential safety hazards. Here are key aspects of disc brake maintenance:

Regular Inspections: Perform visual inspections of your disc brakes at least every 12,000 miles or annually, whichever comes first. Look for signs of wear on the brake pads and rotors, check for any leaks in the hydraulic system, and ensure the caliper moves freely.

Brake Pad Replacement: Brake pads are the most frequently replaced component of the disc brake system. They should be replaced when the friction material wears down to about 3-4 mm thickness. Many brake pads come with wear indicators that produce a squealing noise when replacement is needed.

Rotor Maintenance: Rotors should be inspected for warping, scoring, or uneven wear. They can often be resurfaced if the wear is not too severe. However, if they are below the minimum thickness specified by the manufacturer or show signs of cracking, they must be replaced.

Brake Fluid Changes: Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This can lead to a decrease in boiling point and potential brake system corrosion. Most manufacturers recommend changing brake fluid every 2 years or 24,000 miles.

Caliper Maintenance: Ensure brake calipers are clean and move freely. Stuck calipers can cause uneven brake pad wear and reduced braking efficiency. Lubricate caliper slide pins during brake pad replacements to maintain smooth operation.

Address Unusual Symptoms Promptly: Pay attention to warning signs such as squealing, grinding noises, vibrations during braking, or a soft brake pedal. These symptoms often indicate wear or potential issues that should be addressed immediately to prevent more serious problems.

Use Quality Parts: When replacing components, use high-quality parts that meet or exceed the original equipment specifications. Cheap, low-quality parts may save money initially but can lead to poor performance and more frequent replacements.

Professional Inspections: While many aspects of brake maintenance can be performed by DIY enthusiasts, having a professional inspection periodically can help catch issues you might miss and ensure all components are functioning correctly.

By following these maintenance practices, you can ensure your disc brakes continue to provide reliable, efficient stopping power throughout the life of your vehicle. Regular care not only enhances safety but can also save money in the long run by preventing major repairs and extending the lifespan of brake components.

FAQs About Disc Brakes

- How often should disc brakes be replaced?

Brake pads typically need replacement every 30,000 to 70,000 miles, while rotors can last 50,000 to 70,000 miles, depending on driving habits and conditions. - Are disc brakes better than drum brakes?

Generally, yes. Disc brakes offer better stopping power, heat dissipation, and performance in wet conditions compared to drum brakes. - Can I switch from drum brakes to disc brakes?

Yes, it’s possible to convert from drum to disc brakes, but it requires significant modifications and should be done by a professional. - Why do my disc brakes squeal?

Squealing can be caused by worn brake pads, glazed rotors, or the presence of contaminants. It’s often an indicator that inspection or maintenance is needed. - Do electric cars use disc brakes?

Most electric cars use a combination of regenerative braking and traditional disc brakes for optimal efficiency and safety.