Disc brakes have become the standard in modern vehicles, revolutionizing the automotive industry with their superior performance and reliability. These braking systems utilize a flat, circular disc (rotor) attached to the wheel, which is squeezed by brake pads to slow or stop the vehicle. The popularity of disc brakes stems from their numerous advantages over traditional drum brakes, including better heat dissipation, improved stopping power, and easier maintenance.

Disc brakes work on the principle of friction, converting the kinetic energy of a moving vehicle into heat energy. When the driver presses the brake pedal, hydraulic pressure is created in the brake lines, forcing the brake pads to clamp down on the rotor. This action creates friction, which in turn slows the rotation of the wheel and, consequently, the vehicle.

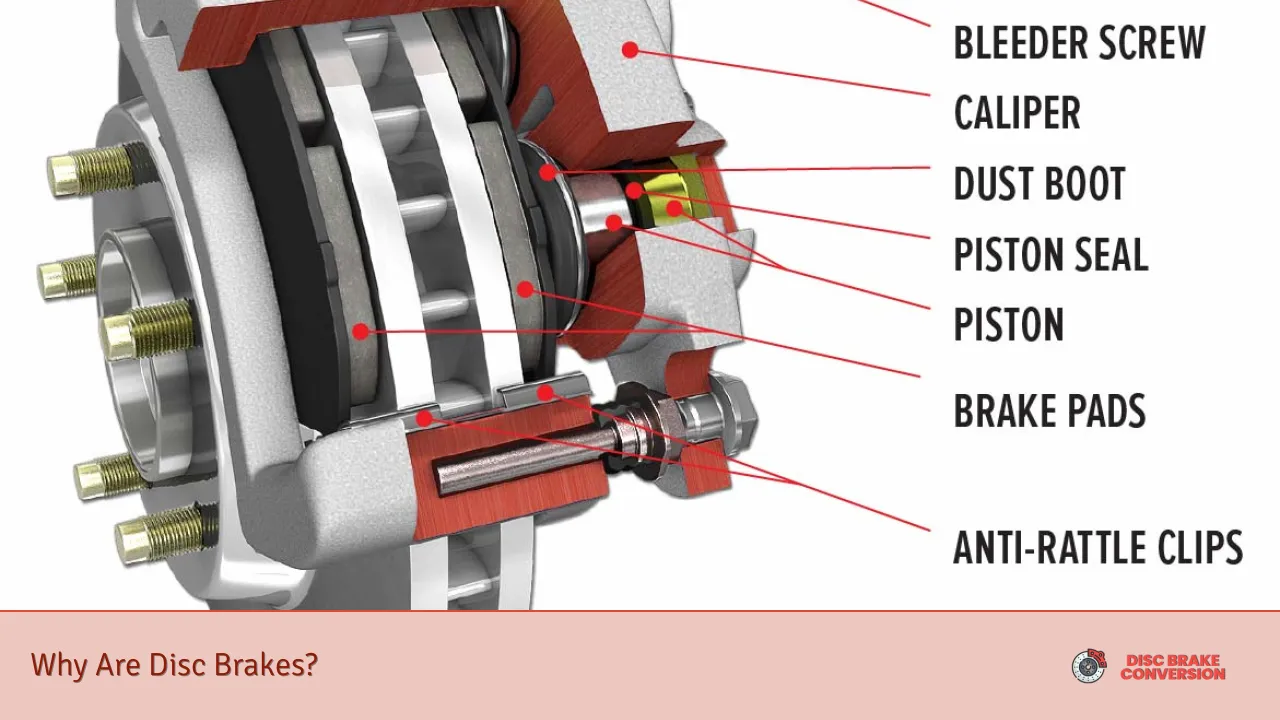

The effectiveness of disc brakes lies in their design and functionality. Let’s take a closer look at the key components and their roles:

| Component | Function |

|---|---|

| Rotor | Rotating disc attached to the wheel that provides the friction surface |

| Caliper | Houses the brake pads and pistons, applying pressure to the rotor |

| Brake Pads | Friction material that presses against the rotor to create stopping force |

| Hydraulic System | Transfers force from the brake pedal to the caliper pistons |

Advantages of Disc Brakes

Disc brakes offer several significant advantages over traditional drum brakes, making them the preferred choice for most modern vehicles. These benefits contribute to enhanced safety, improved performance, and lower long-term maintenance costs.

One of the primary advantages of disc brakes is their superior heat dissipation capabilities. The open design of disc brakes allows for better cooling, which is crucial for maintaining consistent braking performance. As the rotor spins, it naturally dissipates heat into the surrounding air, preventing brake fade during prolonged or heavy braking situations. This feature is particularly important for high-performance vehicles and those that frequently encounter challenging driving conditions.

Another key benefit is the improved stopping power offered by disc brakes. The design of disc brakes allows for a larger contact area between the brake pads and the rotor, resulting in more efficient friction and, consequently, shorter stopping distances. This increased braking efficiency is especially noticeable in wet conditions, where disc brakes significantly outperform drum brakes due to their self-cleaning nature.

Disc brakes also provide better modulation, allowing drivers to apply braking force more precisely. This improved control is due to the linear relationship between pedal pressure and braking force, which gives drivers a better feel for the brakes and enhances overall vehicle control.

Maintenance and Longevity

From a maintenance perspective, disc brakes offer several advantages. The open design of disc brakes makes it easier to inspect brake pads for wear without removing the wheel, simplifying routine maintenance checks. Additionally, replacing brake pads on a disc brake system is generally quicker and more straightforward than servicing drum brakes.

Disc brakes also tend to have a longer lifespan than drum brakes, primarily due to their superior heat dissipation properties. The reduced heat buildup means less wear on the brake components over time, potentially lowering long-term maintenance costs.

Another advantage is the self-adjusting nature of disc brakes. Unlike drum brakes, which may require periodic adjustments to maintain optimal performance, disc brakes automatically adjust for pad wear. This self-adjusting feature ensures consistent braking performance throughout the life of the brake pads and reduces the need for manual adjustments.

Types of Disc Brakes

There are two main types of disc brakes used in modern vehicles: fixed caliper and floating caliper designs. Each type has its own set of characteristics and is suited to different applications.

Fixed caliper disc brakes feature pistons on both sides of the rotor. When the brake pedal is pressed, these pistons push the brake pads against the rotor from both sides simultaneously. This design provides even pressure distribution and is often used in high-performance vehicles due to its superior braking power and heat dissipation capabilities.

Floating caliper disc brakes, also known as sliding calipers, are more common in passenger vehicles. This design features pistons on only one side of the rotor. When activated, the piston pushes the inner brake pad against the rotor, while the caliper itself slides on pins to bring the outer pad into contact with the rotor. Floating calipers are generally less expensive to manufacture and maintain, making them a popular choice for everyday vehicles.

Material Considerations

The choice of materials used in disc brake components plays a crucial role in their performance and longevity. Rotors are typically made from cast iron due to its excellent heat dissipation properties and resistance to warping. However, some high-performance vehicles use carbon-ceramic rotors, which offer even better heat resistance and reduced weight, albeit at a significantly higher cost.

Brake pads come in various compounds, each designed for specific performance characteristics. Common materials include:

- Organic: Quiet operation and low dust, but shorter lifespan

- Semi-metallic: Good heat dissipation and longer life, but noisier

- Ceramic: Low dust, quiet operation, and long life, but more expensive

The choice of brake pad material depends on factors such as vehicle type, driving style, and budget considerations.

Disc Brakes in Different Vehicle Types

While disc brakes are now standard on most passenger vehicles, their implementation can vary depending on the vehicle type and intended use.

In passenger cars, disc brakes are typically used on all four wheels in modern vehicles. However, some economy models may still use drum brakes on the rear wheels to reduce costs. The front brakes in a car do most of the braking work (about 70-80%), which is why disc brakes are always used on the front axle even in vehicles with rear drum brakes.

High-performance vehicles and sports cars often feature more advanced disc brake systems. These may include larger rotors for improved heat dissipation, multi-piston calipers for increased clamping force, and high-performance pad materials for enhanced stopping power. Some exotic cars even use carbon-ceramic brake rotors for ultimate performance and weight reduction.

In the world of motorcycles, disc brakes have largely replaced drum brakes due to their superior performance and lighter weight. Most modern motorcycles use disc brakes on both wheels, with high-performance models often featuring dual discs on the front wheel for increased stopping power.

Heavy-duty vehicles like trucks and buses also benefit from disc brake technology. These vehicles often use air-operated disc brakes, which provide the high braking force required to stop large, heavy vehicles safely. The improved heat dissipation of disc brakes is particularly beneficial in these applications, where the braking system must handle significant loads and frequent use.

FAQs About Disc Brakes

- How often should disc brakes be serviced?

Disc brakes should be inspected every 12,000 miles or annually, with pad replacement typically needed every 30,000 to 70,000 miles depending on driving conditions and habits. - Can disc brakes be retrofitted to older vehicles?

Yes, many older vehicles can be upgraded to disc brakes, but it often requires additional modifications to the wheel hubs, master cylinder, and brake lines. - Are disc brakes more expensive than drum brakes?

Initially, disc brakes can be more expensive, but their longer lifespan and easier maintenance often make them more cost-effective in the long run. - Do disc brakes work better in wet conditions?

Yes, disc brakes perform significantly better in wet conditions due to their self-cleaning nature and open design, which allows water to be quickly dispersed. - Can disc brakes overheat?

While disc brakes are less prone to overheating than drum brakes, they can still overheat under extreme conditions, potentially leading to brake fade.

In conclusion, disc brakes have become the standard in modern vehicles due to their superior performance, reliability, and safety benefits. Their ability to provide consistent stopping power, even under demanding conditions, makes them an essential component of today’s automotive safety systems. As vehicle technology continues to advance, we can expect to see further innovations in disc brake design, materials, and integration with electronic safety systems, ensuring that this crucial safety feature remains at the forefront of automotive engineering.